First ULTRA Low Energy Dryer

The ULTRA Low Energy Dryer is the first in its class of ultra-low energy drying systems.

ULTRA dryers offer quick ROI through energy savings.

WSB Gravimetric Blenders

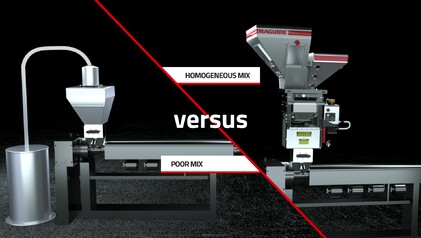

30+ years of experience in Gravimetric Blending. The fundamentals of design for Maguire have always been about accuracy, quick return on investment and ease of use.

The Maguire Gravimetric Batch blender is the most popular blender worldwide, with close to 60,000 running.

MGF Gravimetric Feeders

Maguire’s long-term experience in Gravimetric Dosing has made the MGF a Gravimetric Feeder that provides robust hardware, integrated with industry-leading software control to achieve precision dosing accuracy.

On balance, we're better.

Maguire+Syncro

It’s time to upgrade your existing line. Gain control and start saving with Maguire+Syncro.

Maguire+Syncro offer complete product line ups with all the corresponding product families.

Customers can use existing equipment from Maguire, while easily expanding control elements on both existing and new lines.

Conveying Systems

Maguire offers a wide range of materials conveying solutions for small, medium and large processors and suited to any production set up.

From a single station to plant-wide systems, Maguire can offer solutions.

Maguire News

Maguire ULTRA Dryer - Advancing the Drying Process in the Era of Digitalization

Maguire ULTRA Dryer - Advancing the Drying Process in the Era of Digitalization

Find Out MoreMaguire adds value to its ULTRA product line by integrating FlexBus Lite into the dryers touchscreen controller

Maguire Blenders: Designed to help plastics processors meet growing sustainability goals.

Maguire Products Showcased Its Patented Ultra Range of Vacuum Drying Technology at Fakuma 2021

Maguire Products Showcased Its Patented Ultra Range of Vacuum Drying Technology at Fakuma 2021

Find Out More

New Bridge Breaker for High-Capacity Blenders

New Bridge Breaker for High-Capacity Blenders

Find Out MoreLeading Innovators in the Plastics Raw Materials Handling Industry

Maguire is focused on solving problems for customers, that often result in creating new product categories for the plastics industry. Maguire launched the first ULTRA low energy dryer, pioneered the Gravimetric Batch Blender and developed first user friendly liquid color peristaltic pump... read more

Within each of these product lines the development continues with the launch of several series and particular highlights include the Maxi Batch Blender series and Micro Blender series for special applications are also industry firsts.

The innovative low profile conveying system, LowPro, was developed to support processors with low head room, while offering simple, cost effective loading with many technical benefits over conventional receivers.

The intuitive and accurate range of MGF gravimetric feeders and volumetric feeders expand options for color and additive dosing.

For extrusion control Maguire + Syncro combines a wide range of options and solutions for modular upgrades and gains in production efficiency, starting with combined loss in weight batch WXB blenders and Loss in Weight hoppers.

Maguire is the largest supplier of gravimetric blenders for processors in the plastics industry. There are close to 60,000 blenders running worldwide since Maguire revolutionized blending in 1989. Every year Maguire launches new software and hardware features to the Gravimetric blending line, based on customer feedback and constant research and development.