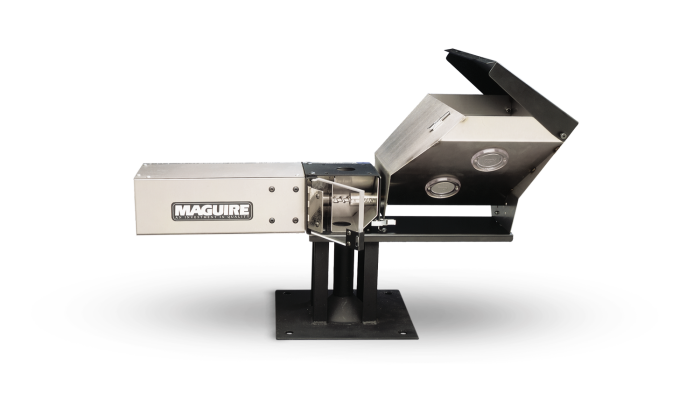

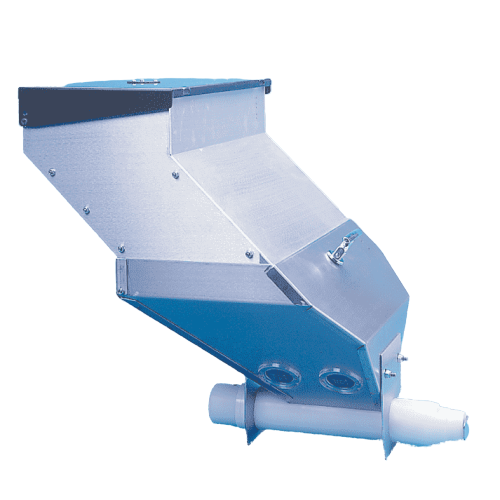

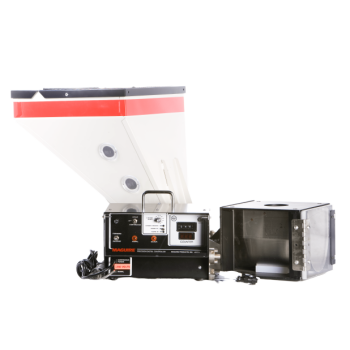

Removable Stainless Steel Hopper

- 0.5 cubic foot (14 L) hopper holds up to 30 pounds (13.5 kg).

- 4 sight glasses for easy view of color level.

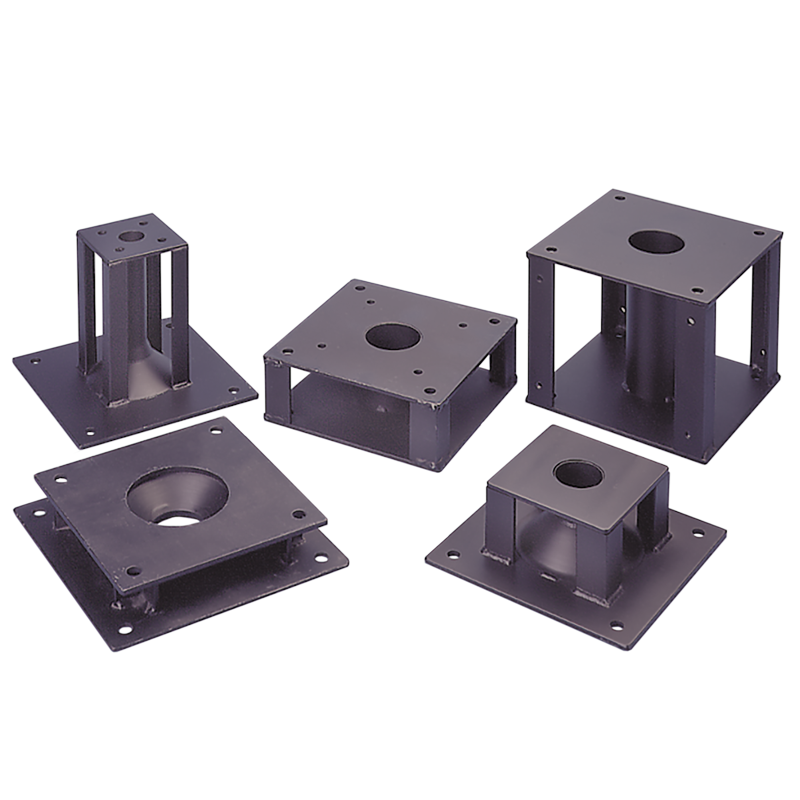

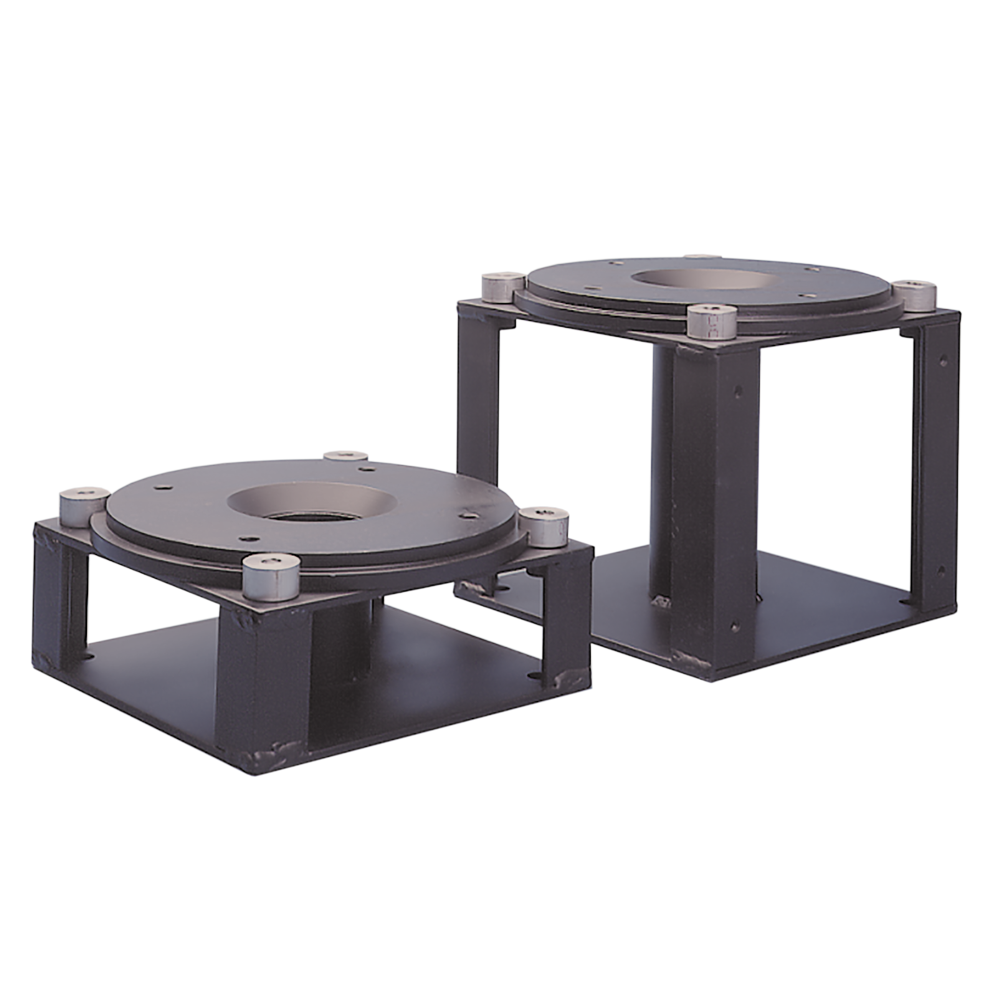

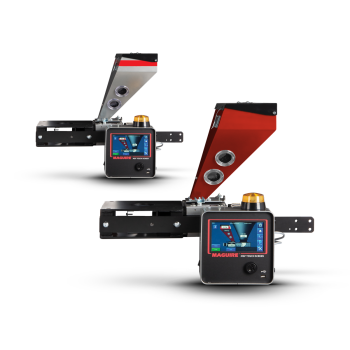

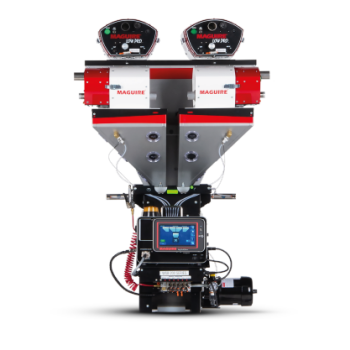

Simple Installation & Access

- Mounted directly over feed throat of machine for easy access.

- Feeder motor positioned on one side, hopper on the other side to evenly balance the weight of the feeder over the feed throat of the machine.

- Remote control configuration further reduces weight of the equipment.