Return on Investment

- MGF software and hardware reduce waste of colorants and additives drastically.

- Maguire Gravimetric Feeders eliminate manual handling and mixing and reduce operation costs.

- Save typically 30% on masterbatch costs compared to manual or volumetric dosing.

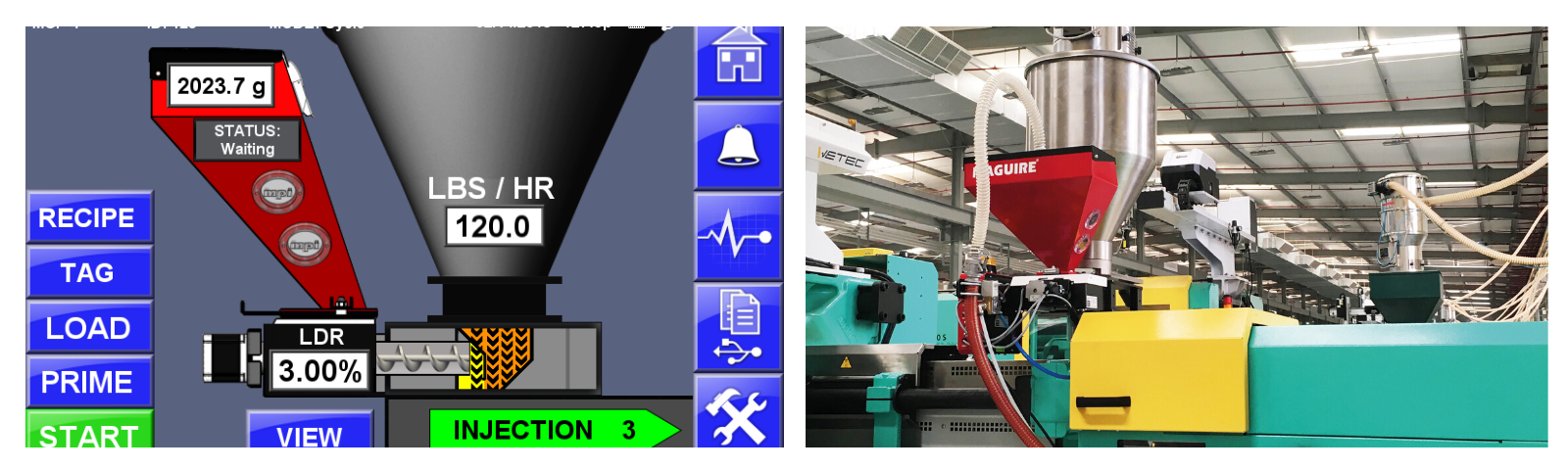

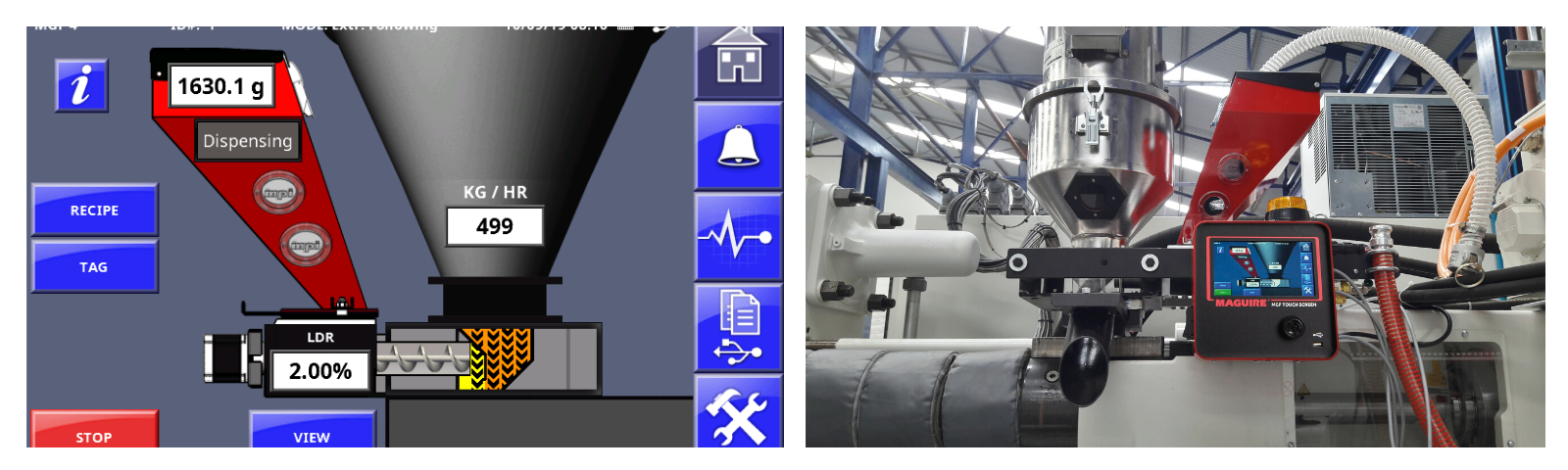

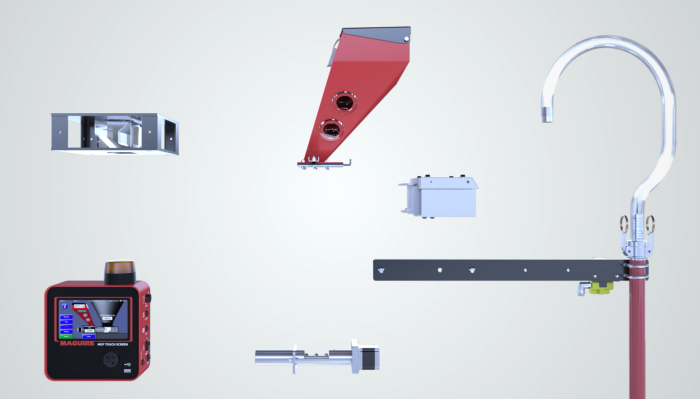

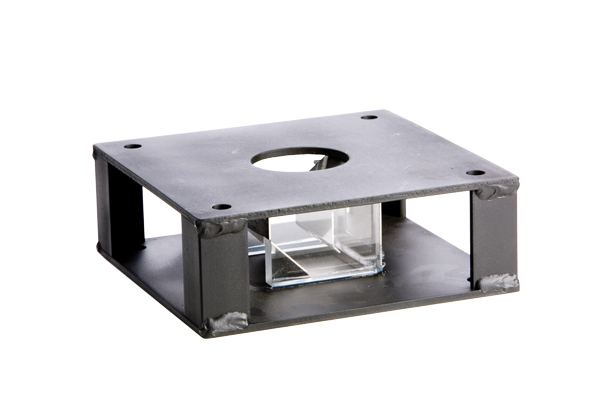

Twin Load Cells

- Lightweight aluminum hopper mounted on 2 load cells which measure the weight of the hopper and the material ONLY.

- Continuously monitors the loss-in-weight as material is dosed and automatically adjusts flow rate.

- Measuring only the hopper and masterbatch allows for finer resolution load cells versus weighing complete feeder assembly and motor. This achieves maximum accuracy and control.

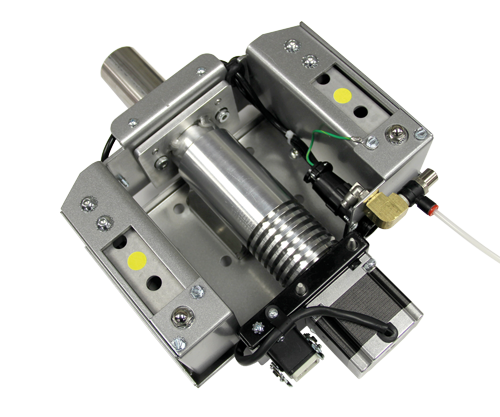

Accuracy of ± 0.2%

- Automatic, continuous updates to flow rate calibration during production process.

- Stepper motor provides high resolution control to dose masterbatch accurately to ± 0.2%.

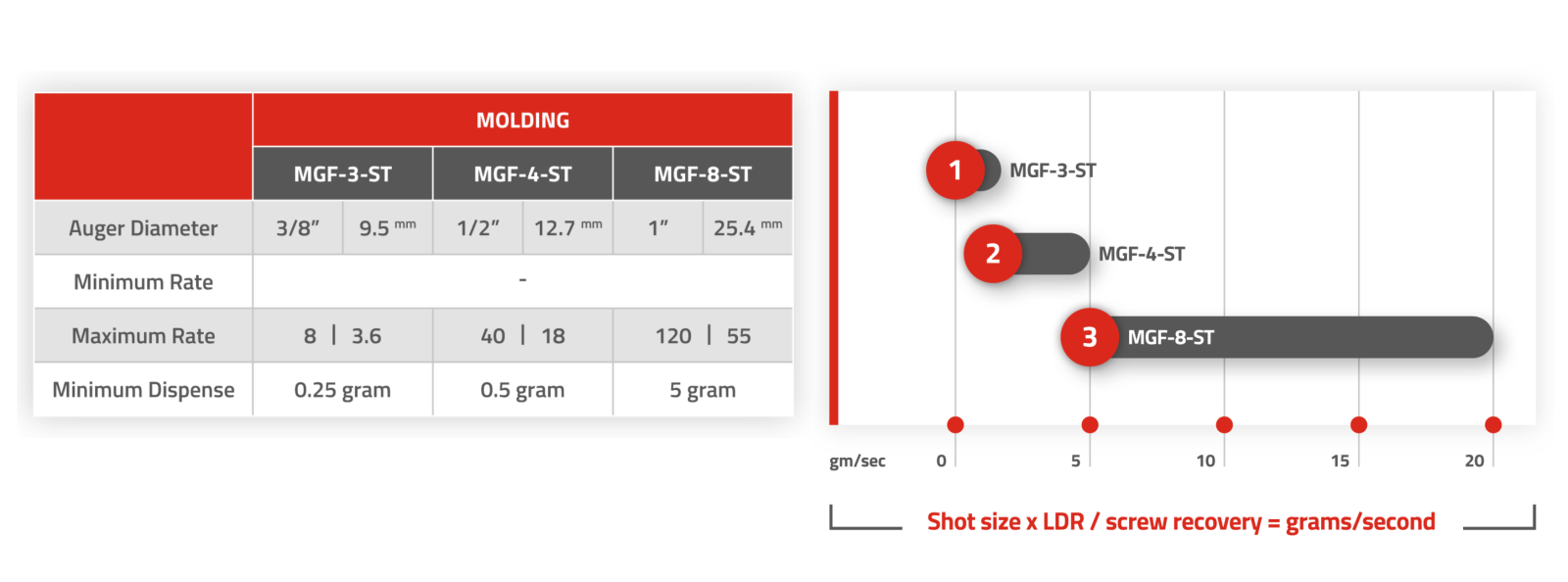

- Choice of dosing screws combined with software control provide industry-leading accuracy.