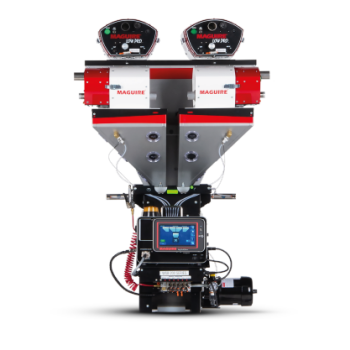

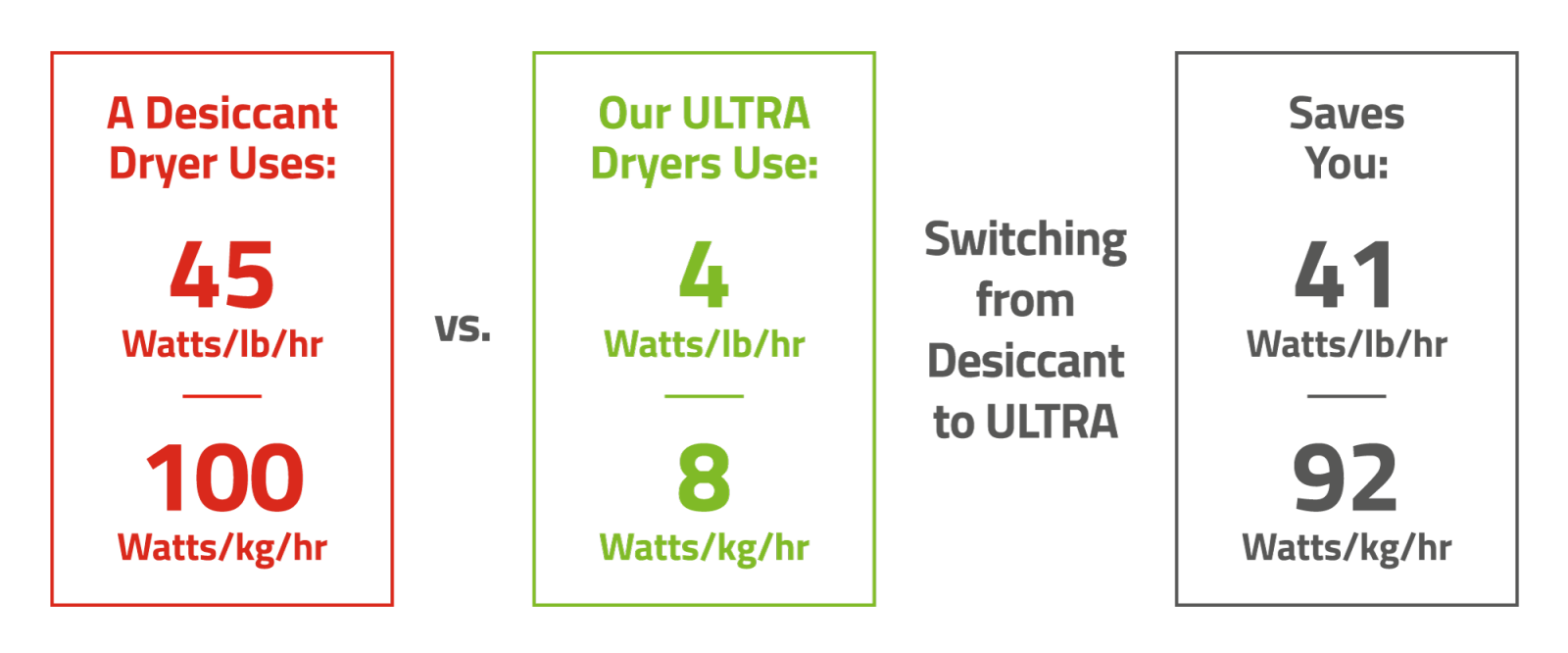

ULTRA Energy - Efficiency Comparison

- kW energy to HEAT raw material from ambient to required drying temperature is the same for all drying processes.

- kW energy to DRY raw material is where the difference occurs, comparing ULTRA dryers to all Desiccant dryers.

ULTRA Low Energy - Operating Cost Savings

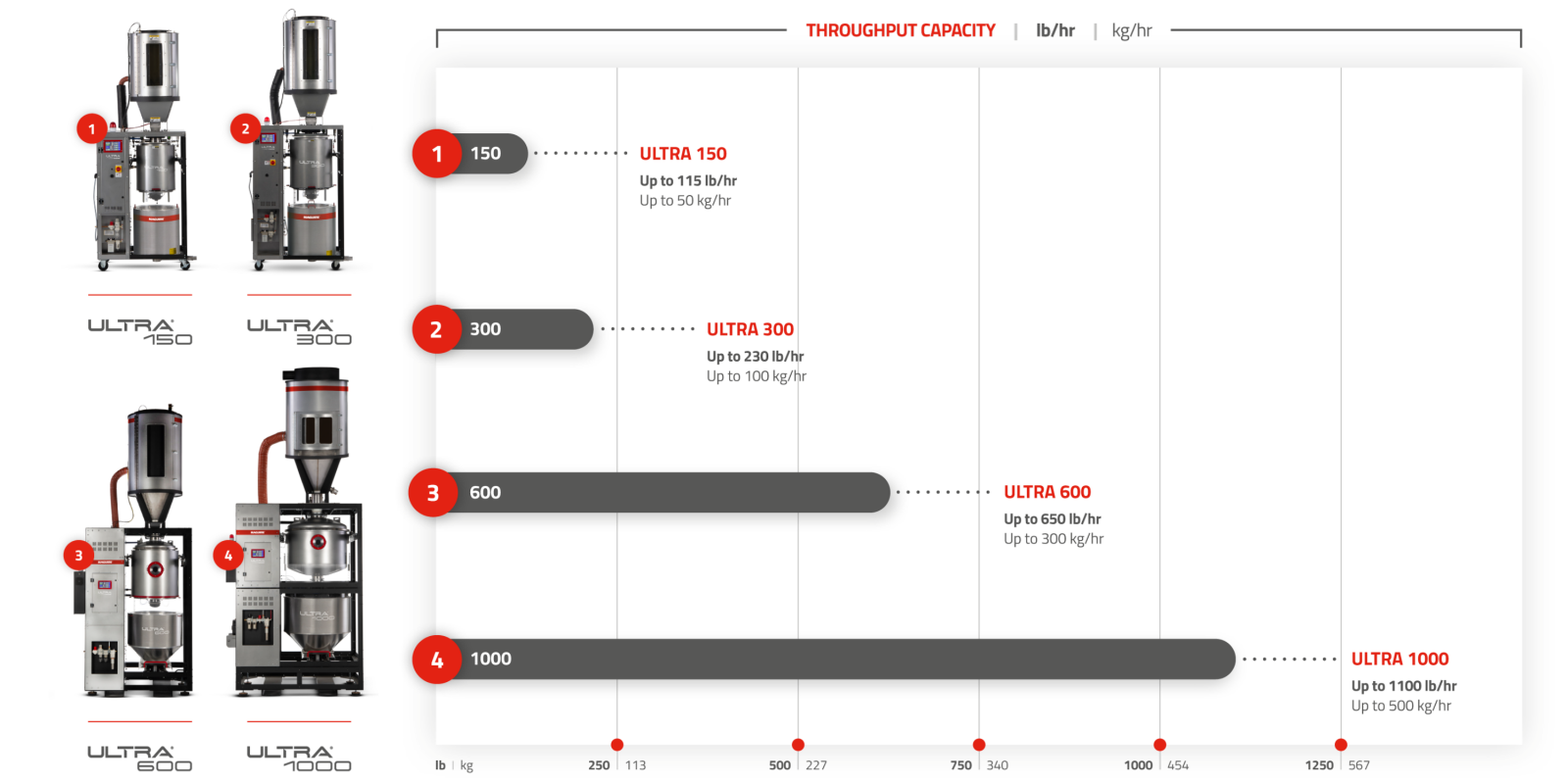

- A process running at 220lb/h (100kg/h) can typically see a kW difference of 41 Watts/lb (92 Watts/kg) with ULTRA dryers versus generic desiccant dryer.

- This saves $6,500 annually at an example rate of 220lb/h (100kg/h) - whilst doing the exact same job.

- ULTRA delivers savings year on year for its full life cycle.

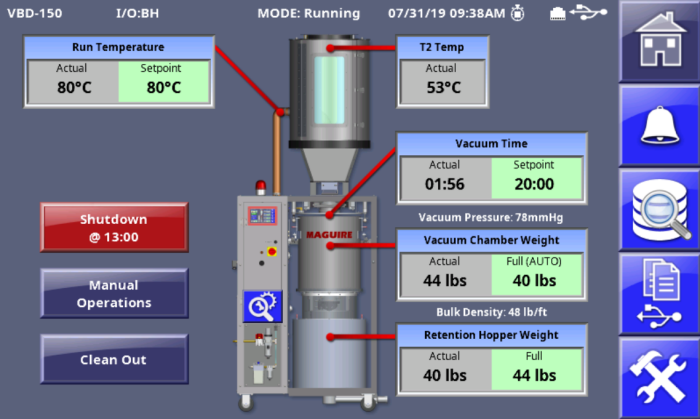

ULTRA Low Energy - Dynamic Software

- Temperature Sense Control – temperature is controlled efficiently with energy saver as standard.

- Heater and air flow are automatically regulated to ensure only the required amount of heat and air flow are used to bring material up to temperature.