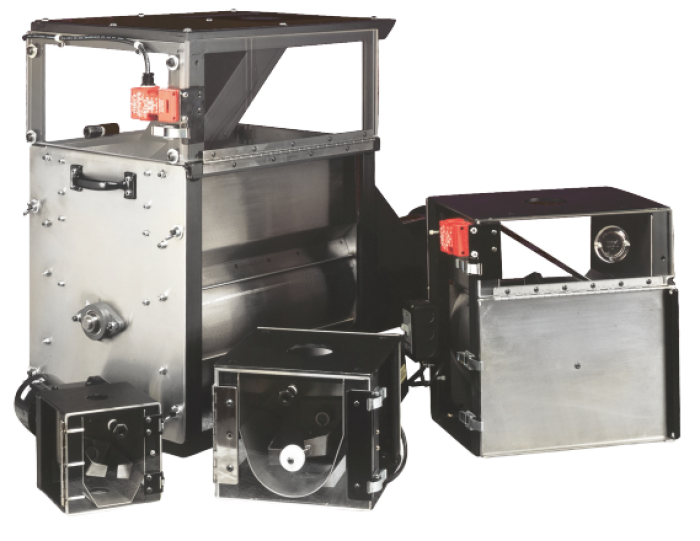

Series MPM Pre-Mixers automatically and continuously provide thorough mixing of resin, regrind and additives as they enter the throat of the process machine.

These mixers are designed to mount directly to the feed throat of the process machine with hopper and hopper loader mounted directly above.

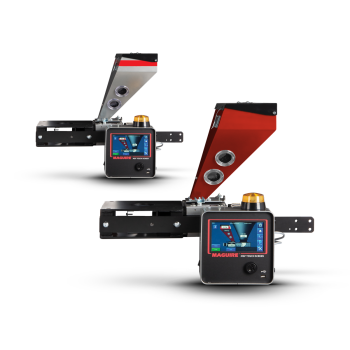

When adding liquid color, masterbatch or other additives, the Maguire Pre-Mixer ensures a homogeneous blend, and coloring is more efficient.

Color consistency of the finished product is improved, and problems such as streaking are virtually eliminated.