(Maguire, Aston, PA, October 12, 2021) … Since Maguire first launched the Vacuum Dryer in 2000, several generations have been produced bringing unique benefits to plastics processors. Processers now benefit from faster drying times and the highest level of drying management and control of the entire drying process.

The Benefits of Vacuum Drying vs Desiccant Dryers

The unique patented vacuum design, (most recent patent #10751918 granted in 2020), allows users to dry materials by use of vacuum and not by dry air as done with desiccant designs. Although both desiccant and vacuum systems use heat to bring the resin up the temperature, the Maguire ULTRA dryer uses a low energy venturi to pull a high vacuum on the heated resin creating a pressure and temperature differential that releases the moisture from the material. This fast, modern and efficient process takes a fraction of the time compared to desiccant dryer designs. A desiccant dryer process, which relies on dry air monitored by dew point, requires constant circulating airflow through a large drying hopper. This process can take 4-6 hours to achieve the same drying results that the ULTRA can do in under 60 minutes. With this vacuum design, there is also no need to replace desiccant every 12-18 months.

Making the Drying Process Smarter

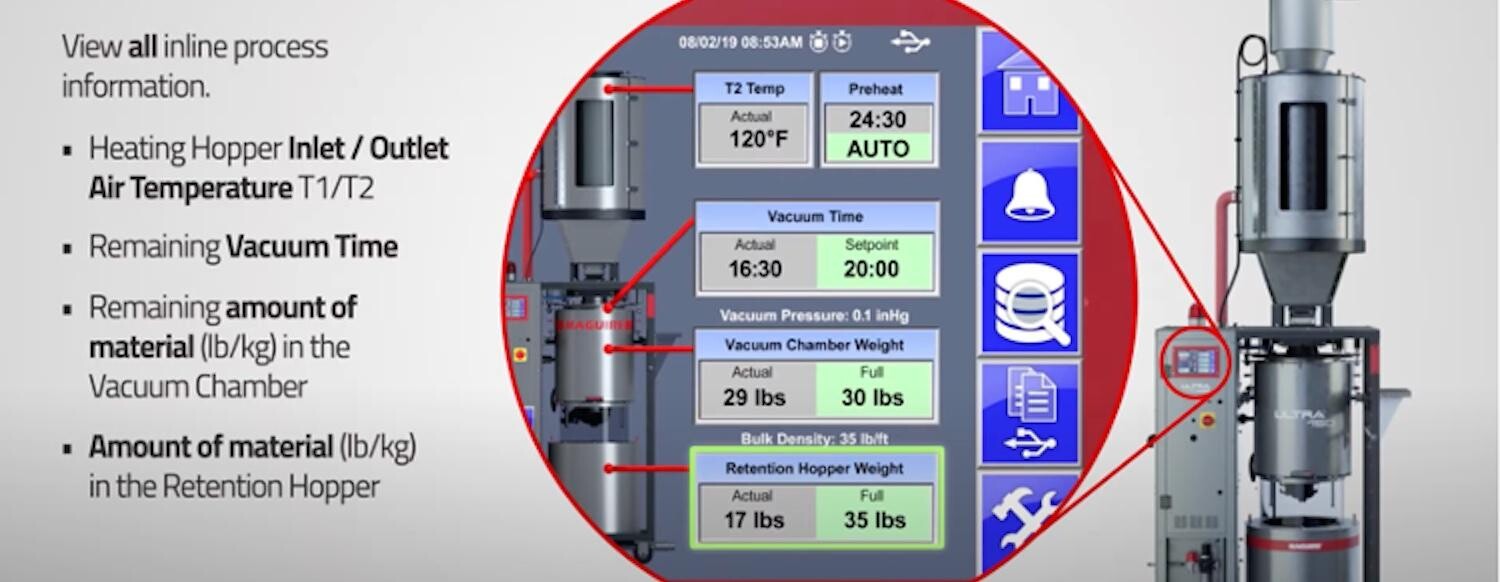

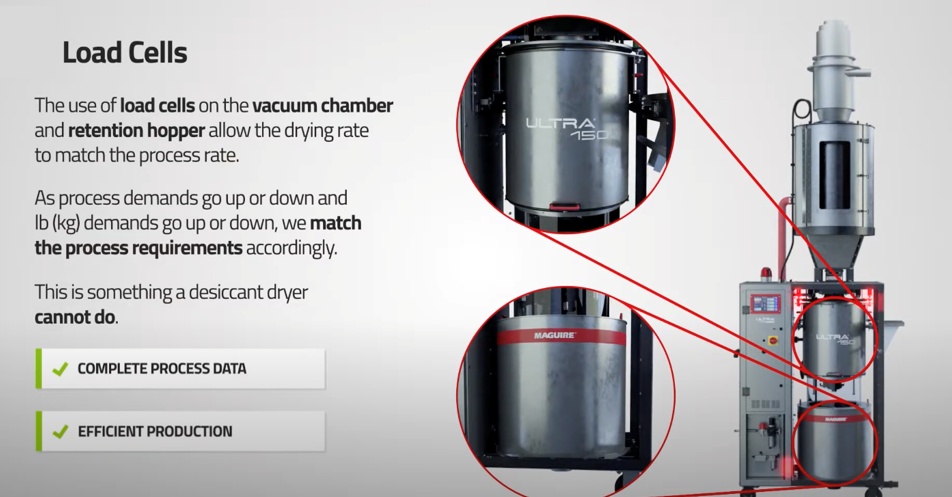

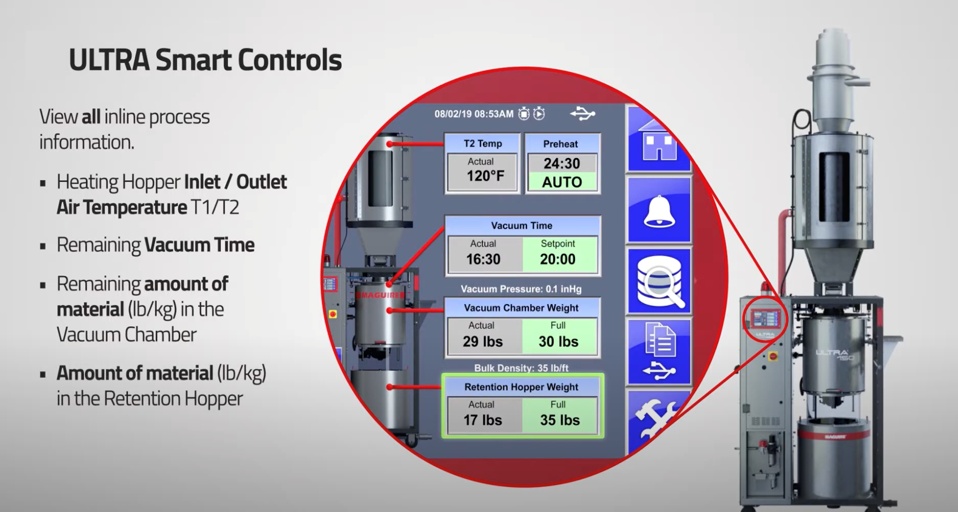

Maguire ULTRA dryers provide the operator the ability to monitor and control each step of the drying process allowing for process optimization throughout the entire drying cycle. With the use of load cells and the advanced control, the operator can:

- monitor and reduce heat with ESL Energy Saving Control (within Heating Hopper),

- create high vacuums in minutes with the ability to shutoff and hold vacuum (within Vacuum Chamber), and

- monitor and adjust material usage live and on demand (within Retention Hopper).

By actively monitoring the vacuum process and the material weight within the vacuum chamber, the system will only dry what’s required. The weight of material in retention hopper is also monitored to only release fresh material when it’s required by the process.

How the ULTRA Digitizes the Drying Process

All this process data allows the system to make adjustments that impact the process automatically. With the start-up safety features the ULTRA software continuously monitors key drying parameters like heating and vacuum, and actively alarms if those are not being adequately met, providing valuable information to the operator.

These smart controls also allow for on-demand drying. The system automatically adapts to dryer demand with features like energy saver mode for heating, not releasing fresh material to the process until it’s required, plus smart features to allow for auto stop of the process to end the dryer on empty. All of this saves energy (up to 90% over competitive drying methods), saves time and can be monitored continuously.

By digitalizing the process, every granule within the drying system is actively monitored and controlled. The data can easily be viewed on the touchscreen and details of the exact operating process as it happens are logged, giving the user a clear understanding of how the material has been dried. In addition, all of this data is available for export for integration with any ERP or other process control systems.

Benefits of Digitalization

By actively controlling the ULTRA drying process the operator is no longer reliant on interacting with the dryer for many drying procedures that would have to be manually checked, monitored or scheduled in the past, freeing up production time and making for a more responsive process.

The easy-to-use touchscreen allows complete data in the hands of the operator. It allows for full automation of many routine functions such as Auto Start, Auto Stop and Dynamic Drying which uses the load cell data to automatically adjust the drying rate to the process rate.

“Knowledge is power and with ULTRA’s control system we are offering the operator information on what is happening with every pellet within the system,” said Frank Kavanaugh, Vice President of Sales and Marketing. “Digitalization of the entire process allows regulation of the drying rate to be tied directly to the process rate. This provides the operator the ultimate flexibility to program a startup or shutdown to any specific day and time. Energy savings, faster drying times, less waste and quick material changes all contribute to the unrivaled value ULTRA dryers bring to the plastics processor.”

Contact Maguire for more information at 610-459-4300 or [email protected]

##

About Maguire

Headquartered in Aston, Pennsylvania, USA, Maguire manufactures gravimetric blenders and feeders, volumetric feeders, ULTRA low energy dryers, conveying systems, extrusion control systems, loss in weight extrusion control, and related auxiliaries.

Founded in 1977, Maguire Products operates seven manufacturing facilities in Aston, with seven international subsidiaries that service an xtensive network of distributors globally.