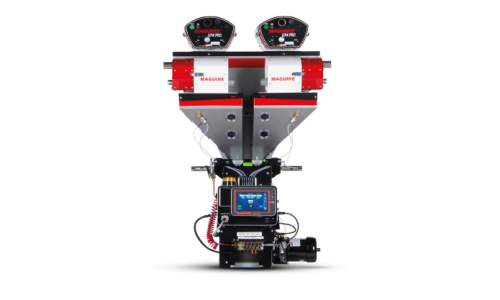

WSB Gravimetric Blenders

Manage machine vibration, reduce scrap and control color & additive usage.

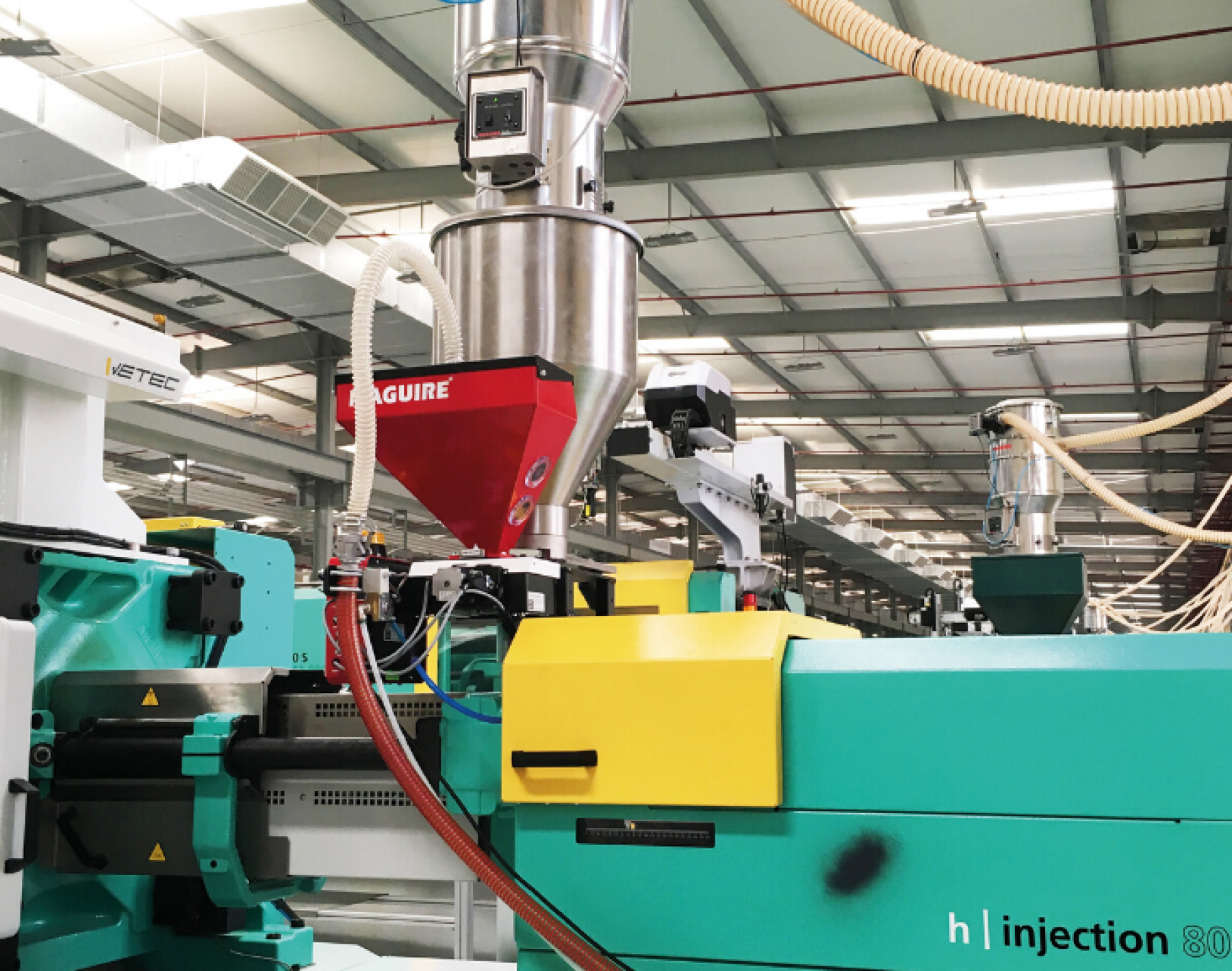

Maguire offer Injection Molding processors complete raw materials handling solutions for blending, dosing, drying, and conveying.

Maguire works with thousands of molders globally in all types of industry providing solutions for dosing liquid colors and masterbatches, to blending solutions to manage blends of 2 or more materials for things like close looping Regrind, introducing Recycled, controlling prime Naturals and minimizing costs of Masterbatch and Additives.

For Drying technical materials Maguire have pioneered the ULTRA vacuum dryer, the ultra-low energy drying system that dries materials at the lowest kW per lb/kg, as well as the ability to dry materials typically 6 times faster than conventional dryers.

With 30+ years of Injection Molding application experience, backed with thousands of installations globally, Maguire have supplied the broadest range of molding industries with many examples including Automotive, Medical, Housewares, Packaging, Education & Toys, Technical, Electronics, Agriculture.

Manage machine vibration, reduce scrap and control color & additive usage.

ULTRA low energy drying. Reduced drying times.

100% injection coloring feature. High heat option. Fast-track calibration.

Material conveying solutions for small, medium & large applications.

Energy efficient drying

Easy and precise metering of liquid color & additives.

Smart unloading for gaylords & octobins.

Ideal for individual conveying applications for single and multiple material stations.

Clear-Vu™ receivers for easy visual status on loading.

Premium Clear-Vu™ bodied loader, ideal for critical single station materials loading.

Volumetric feeders for granule, powder, regrind and liquid.

Transform purgings into high quality regrind.