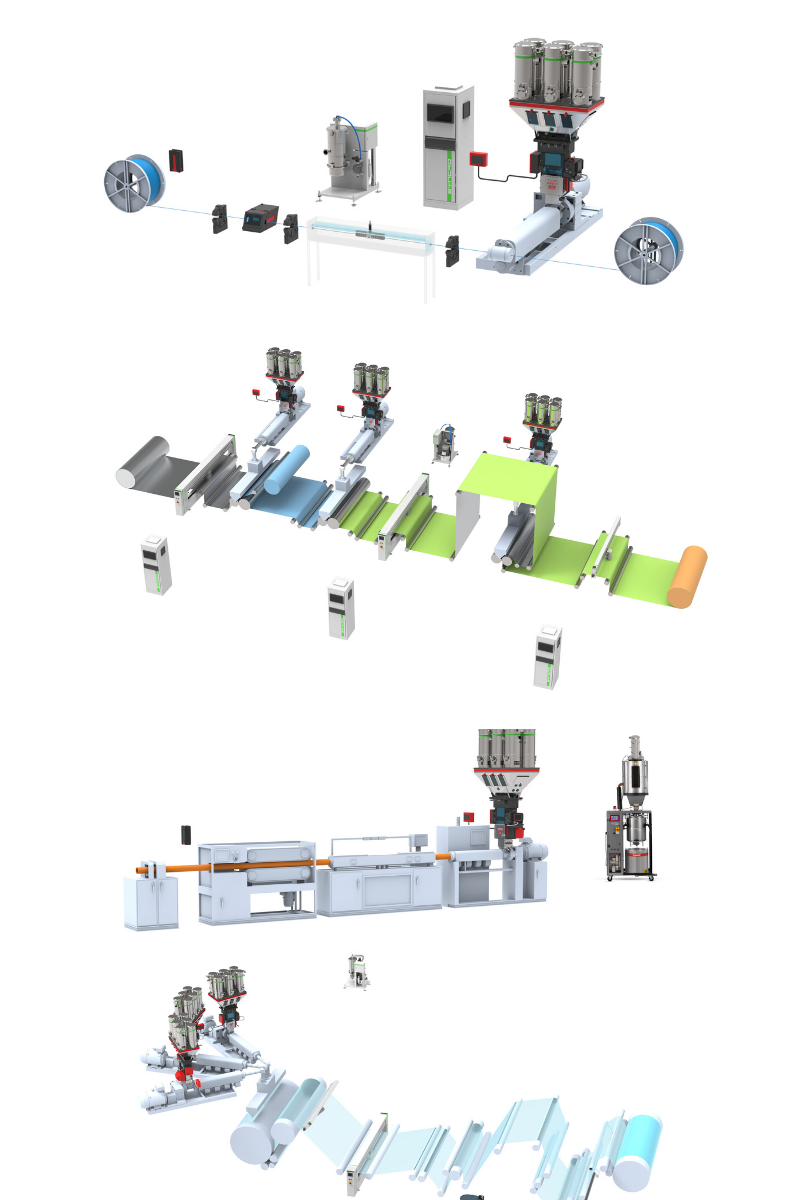

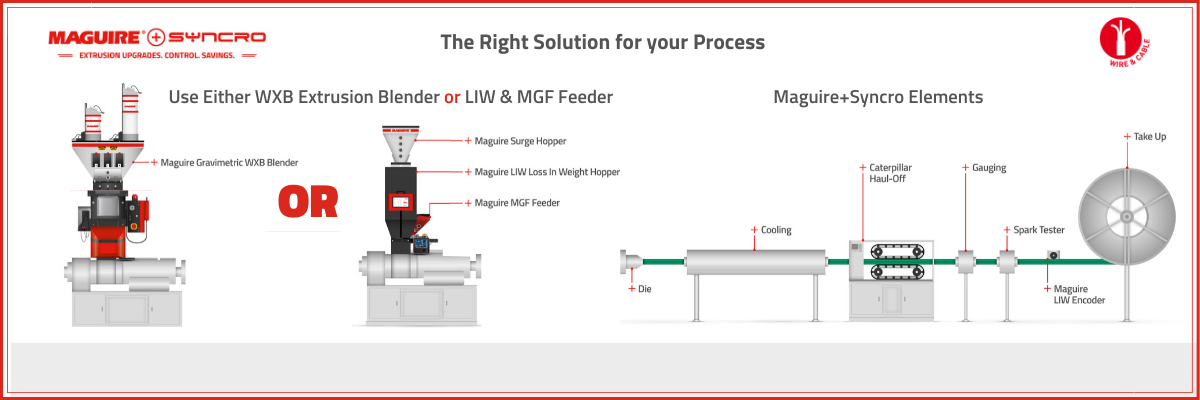

Integrated Blending & Extrusion Control

- Maguire’s proven WXB Gravimetric batch blending technology combined with comprehensive loss-in-weight control.

- Batch blending from 2 - 12 materials with dispense accuracy of +/- 0.1% on a 1% setting.

- Integrated Loss-in-Weight control monitoring live consumption rate to an extruder and updating process rate every second.

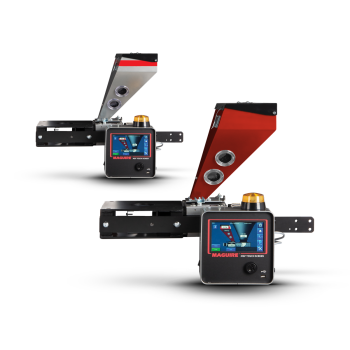

Maguire + Syncro Syntrol Control

- Maguire + Syncro specialist extrusion control for every type of extrusion process.

- Syntrol touchscreen allows quick and easy setup of extrusion process.

- Easily set process parameters like gram/meter, micron and layer ratios.