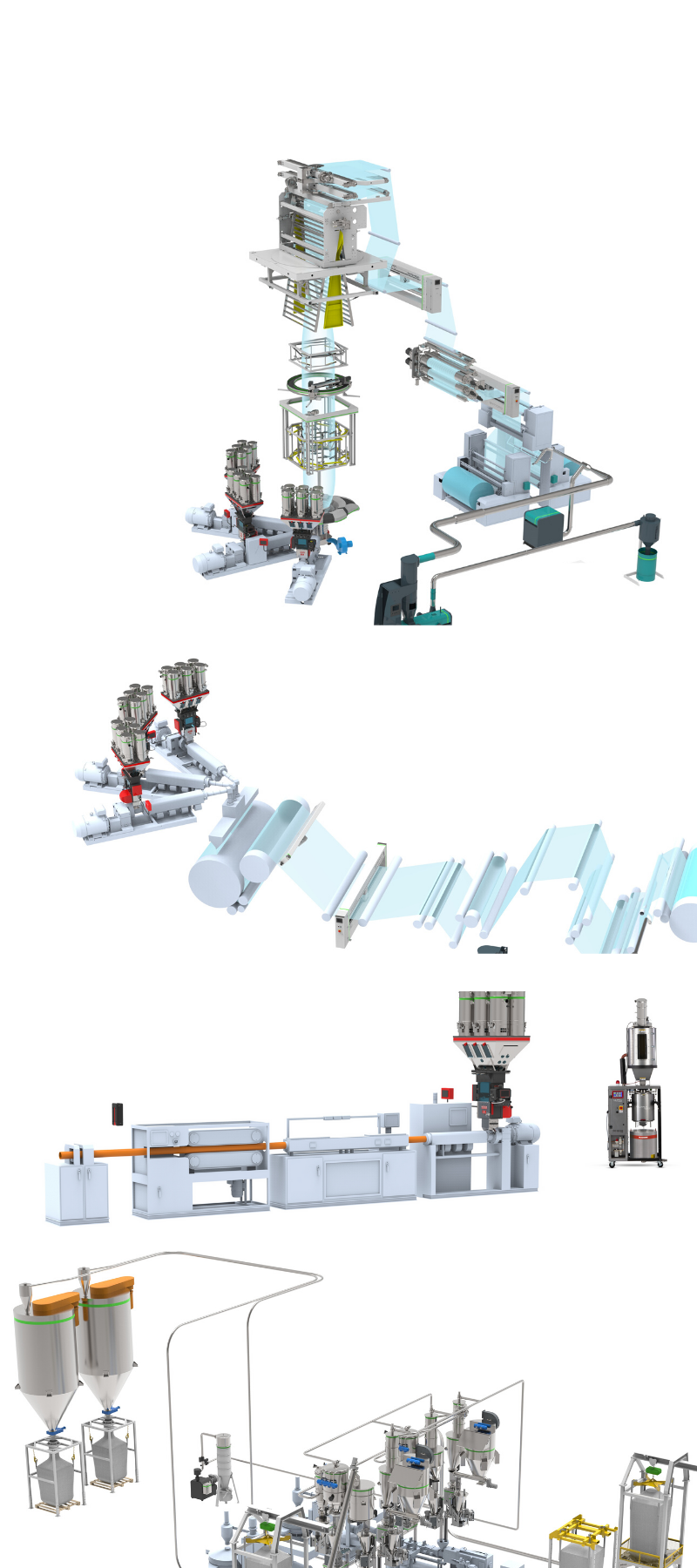

Extrusion control regulates the extrusion and haul off continuously, ensuring material usage control of the line.

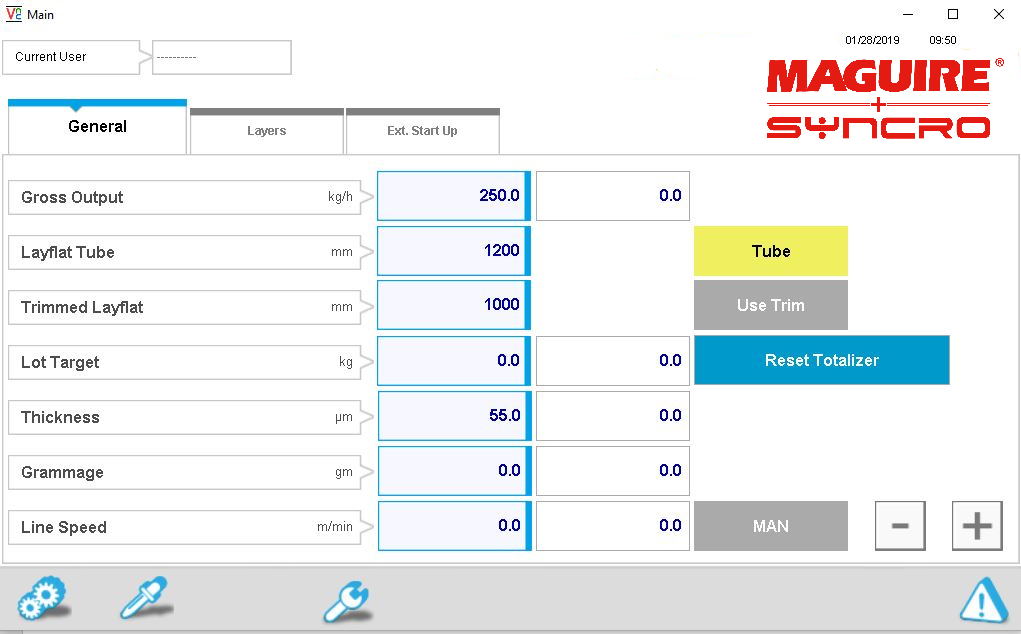

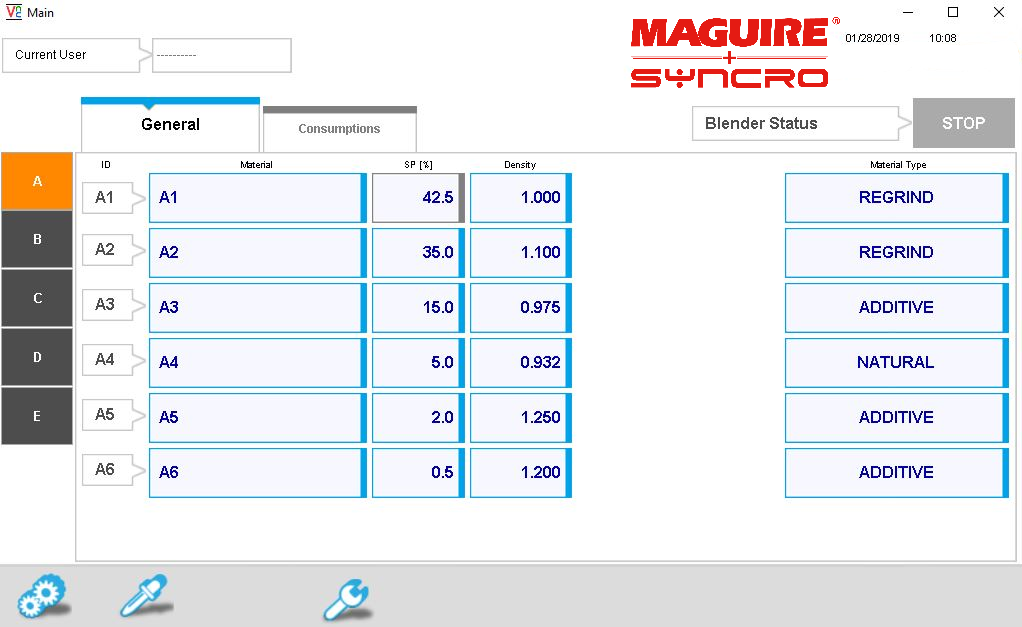

Syntrol Extrusion Control manages the target setpoint of the line, controlling setpoints such as lb/hr, kg/hr, gr/m, lb/ft and micron, optimizing extruder operation and overall linespeed.

More Efficient Start-Ups & Changeovers

- Automate a line startup by simply entering target output requirements.

- Compared to manual startup, reduce startup time by up to 70%.

- Reduce startup material waste and associated material cost.

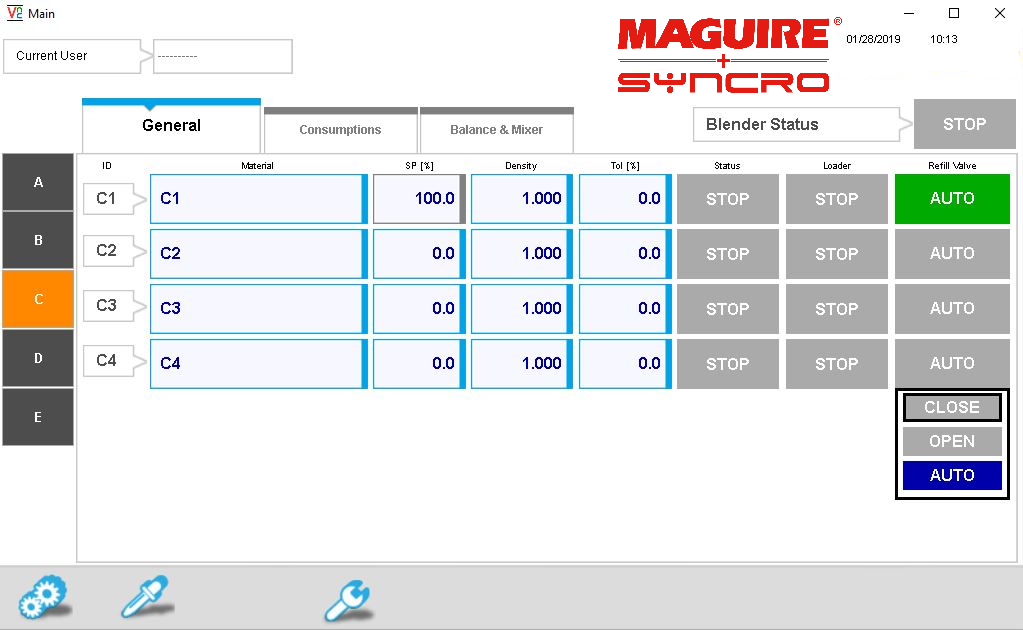

How Extrusion Control Works

- Constant updates of kg/hr, lb/hr usage every second to each extruder.

- Real time monitoring of line speed.

- Precise and automatic regulation of line target output.

- Dynamically versus manual check and adjustments significantly simplify the operator control.

- Improved control on raw material costs by immediate regulation and better materials use.

Increased Productivity

- Quicker & automated start-ups.

- Continuous line monitoring keeps the product setpoints on target - 24 hours a day.

- No drift or manual interventions.

- Benefits on improved product quality and tighter product specification.

- Typical return on investment of 3- 6 months.

- Allow for clear, direct savings in materials and production time.