A critical factor on from materials blend and extrusion control for the performance of a blown film line is the Air Ring.

Upgrading an older Air Ring can deliver significant performance benefits for any blown film line.

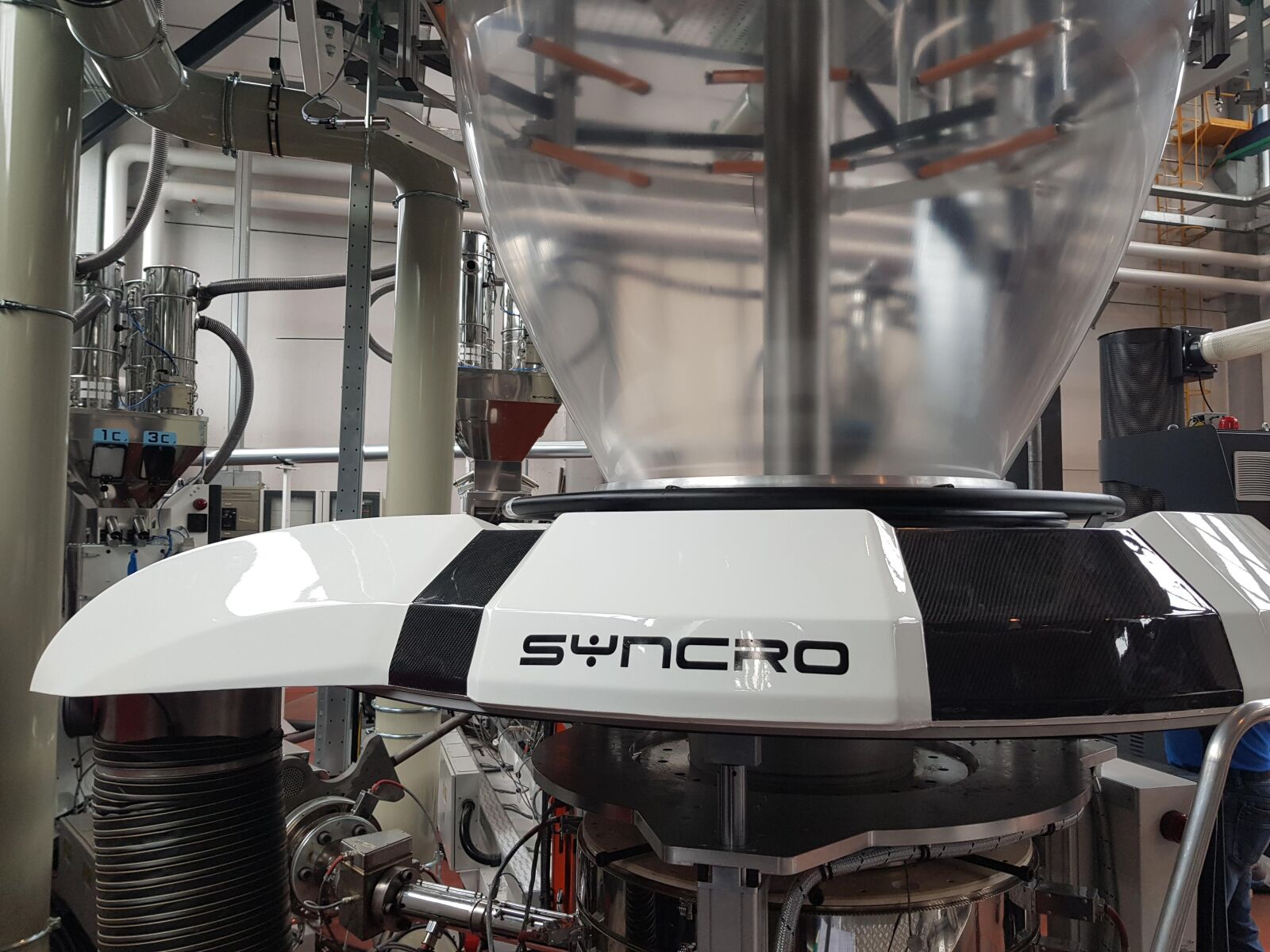

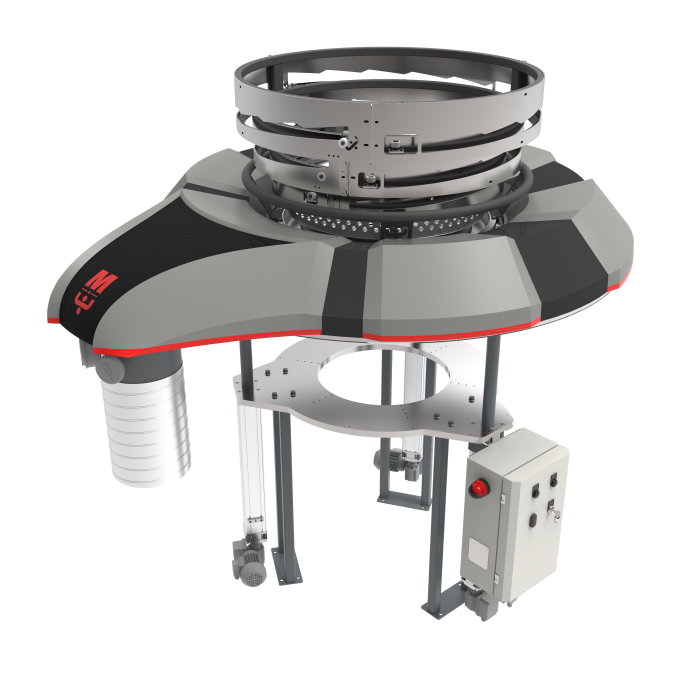

Maguire + Syncro offer 2 types of air ring according to product specifications and productivity drivers;

Typhoon – Dual Lipset – one lipset engineered with 2 air streams to optimize stability and cooling, enabling increases in output.

Flyer – Triple Lipset / Counterflow Air Ring – one lipset engineered with 3 air streams, cooling above and below the air ring to optimize further stability and cooling, enabling increases in output.

- Ensure better air flow distribution by design of M+S Air Rings.

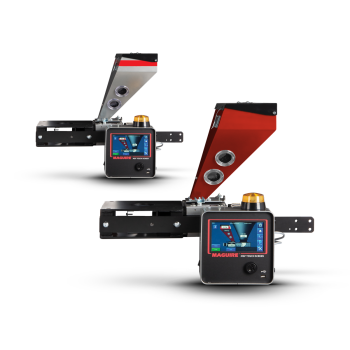

- Gain control of product tolerances with up to 75% improvement at 2 Sigma (2S / 2σ).

- Maximize cooling efficiency with efficient air distribution by design – optimize air flow but minimize pressure losses.

- Control and better cooling expedite better bubble stability – guaranteed.

- Carbon fiber build option for moisture free process.

- Single Inlet and overall design – ensures easier access around the die for maintenance, setup, and control

- Optional modular add-ons in combination with an Air Ring can include, IBC and Automatic Profile Control (APC) of the bubble with wide range of Gauging options.

See the rest of the Maguire+Syncro range here.