- The value of integrated data for proper production planning and control contributes enormously to the planning and control of most plastics processors’ largest cost – raw materials.

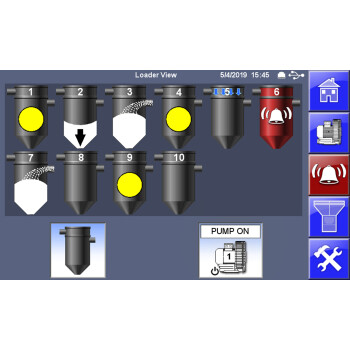

- Many of Maguire products are available with communication protocol including products such as Maguire Gravimetric Blenders, Gravimetric Feeders, FlexBus Central Systems Control and ULTRA dryers.

- Benefits of active data provide far greater control and process understanding.

- For example, Maguire Maguire Blenders provides precise information on materials consumption allowing for better control of inventory, improved purchase planning, quality control, data for ISO and proper planning for job costing.

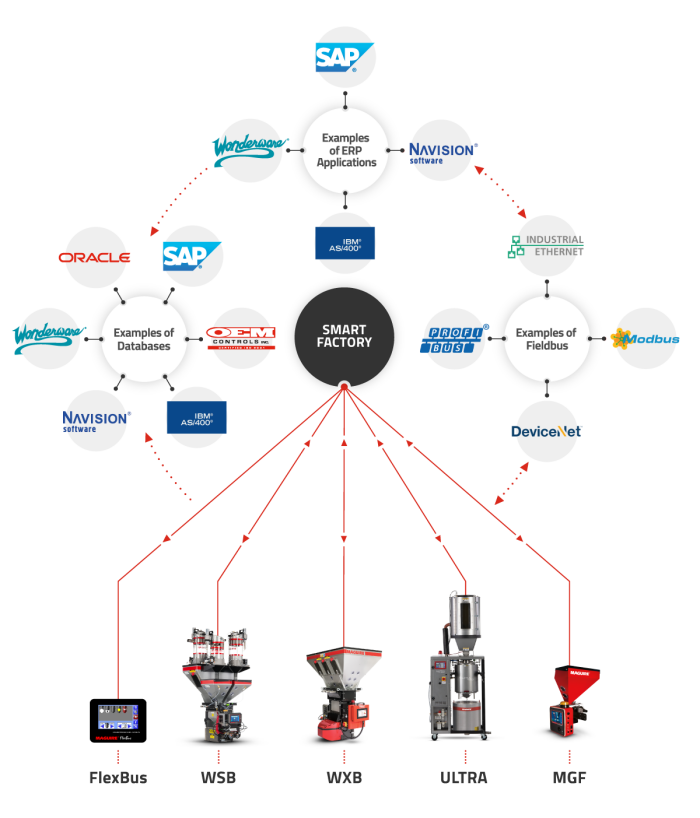

Third-Party Integrations

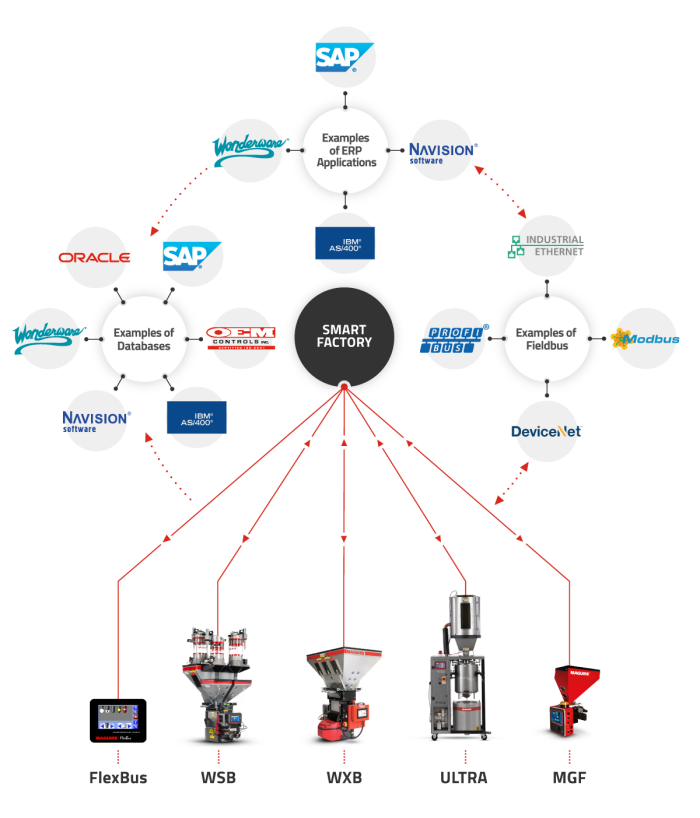

With IoT and Industry 4.0, integrated manufacturing is ever the more important for effective and efficient control.

- Protocols available for majority of Maguire equipment

- Range of third-party integrations available

- Led by a broad range of customers & applications

Integration Benefits

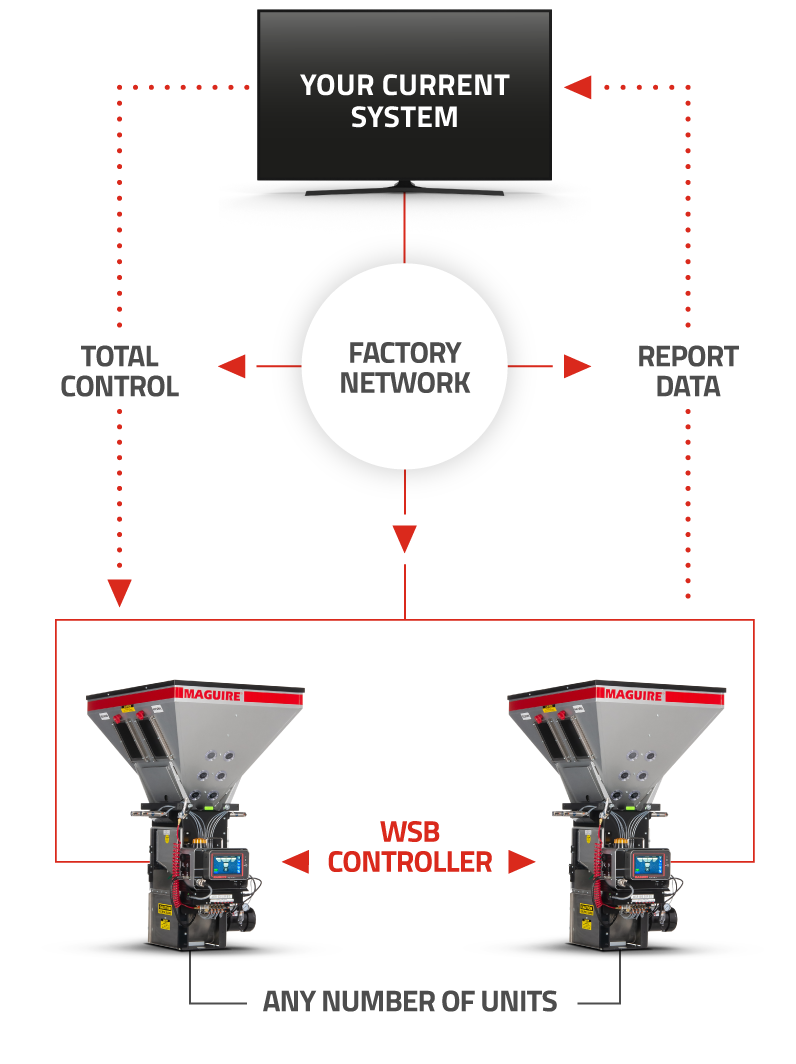

Network Integrations

Connections can either be at a software level utilizing SQL or OPC based links, or alternatively machine to machine communications via Maguire’s open source MLAN protocol, or industry leading fieldbus protocols such as Industrial Ethernet, Profibus, DeviceNet and Modbus TCP/IP. Examples of these have included:

Application Integrations

These include Central PLC Control Panels, SCADA systems, Plant Wide Control Systems, or Accounting Systems managing materials stocks. Examples of these have included:

Third-Party Communications at a Glance

1. ERP Applications

Customers can connect third-party ERP applications, such as SAP and Wonderware, to Maguire products.

3. Database Integrations

These include Central PLC Control Panels, SCADA systems, Plant Wide Control Systems, or Accounting Systems managing materials stocks.

2. Network Integrations

Connections can be machine to machine communications via Maguire’s open source MLAN protocol, or industry leading Fieldbus protocols such as Industrial Ethernet, Profibus, DeviceNet and Modbus TCP/IP.

4. Integration Benefits

Many of Maguire products are available with communication protocol including products such as Maguire Gravimetric Blenders, Gravimetric Feeders, FlexBus Central Systems Control and ULTRA dryers.

G2 and MySQL

The Maguire G2 database can be located in a MySQL database server to allow customers to connect to third party interfaces, such as SAP, that connect to a MySQL database. MySQL is a stable, reliable and powerful solution with advanced features.

Ease of Use

- MySQL is easy to install and create recipes from. It can simply be added to many third-party tools that can be connected to the database.

Free Installation

- Should customers want to use MySQL with G2, installation is free and easily accessible.

Universal Platform

- The database is compatible with virtually every operating system to enable you to integrate with your current systems.

Extremely Powerful, Secure and Scalable

- MySQL is the de facto standard for high-traffic websites because of its high performance query engine, fast data insert capability and strong support for specialized web functions like fast full text searches.

Flexibility

- On-demand flexibility is a key feature of MySQL. This open source solution allows complete customization to those with unique database server requirements.

Anybus Gateway

Anybus provides two-way communication between all Maguire Weigh Scale Blender’s MLAN protocol and 15 major networks.

Seamless Configuration

Anybus provide seamless conversion from MLAN Protocol to these 15 major fieldbus and industrial Ethernet networks:

- Fieldbus versions: Profibus, CANopen, CC-Link, ControlNet, DeviceNet, FIPIO, Interbus, Modbus Plus, Modbus RTU.

- Ethernet versions: EtherNet/IP, Modbus TCP, EtherCAT, Profinet, CC-Link IE Field, EtherNet/IP/MTCP 2-port.

Compatibility

- Compatible with all leading PLCs from manufacturers such as Siemens, Allen Bradley, Schneider etc.

Control

- Remote access to blender display and start / stop of dispensing.

Easy Setup

- Easily create set and get setpoints, types and parameters according to your requirements.

Maguire has developed profiles with Anybus. Anybus profiles are available to purchase from Maguire.

Kepware

KEPServerEX – Communications Platform

Kepware's software solutions for the Industrial Automation Industry bridge the communication gap between diverse hardware and software applications.

- KEPServerEX and the U-CON (User-Configurable) Driver are flexible and scalable solutions for connecting, managing, monitoring, and controlling automation devices that support the protocol.

- Client communications are managed through a robust platform that supports an array of open standards, proprietary communication protocols, APIs, and automation system interfaces.

- KEPServerEX improves operations and decision-making throughout all levels of an organization.