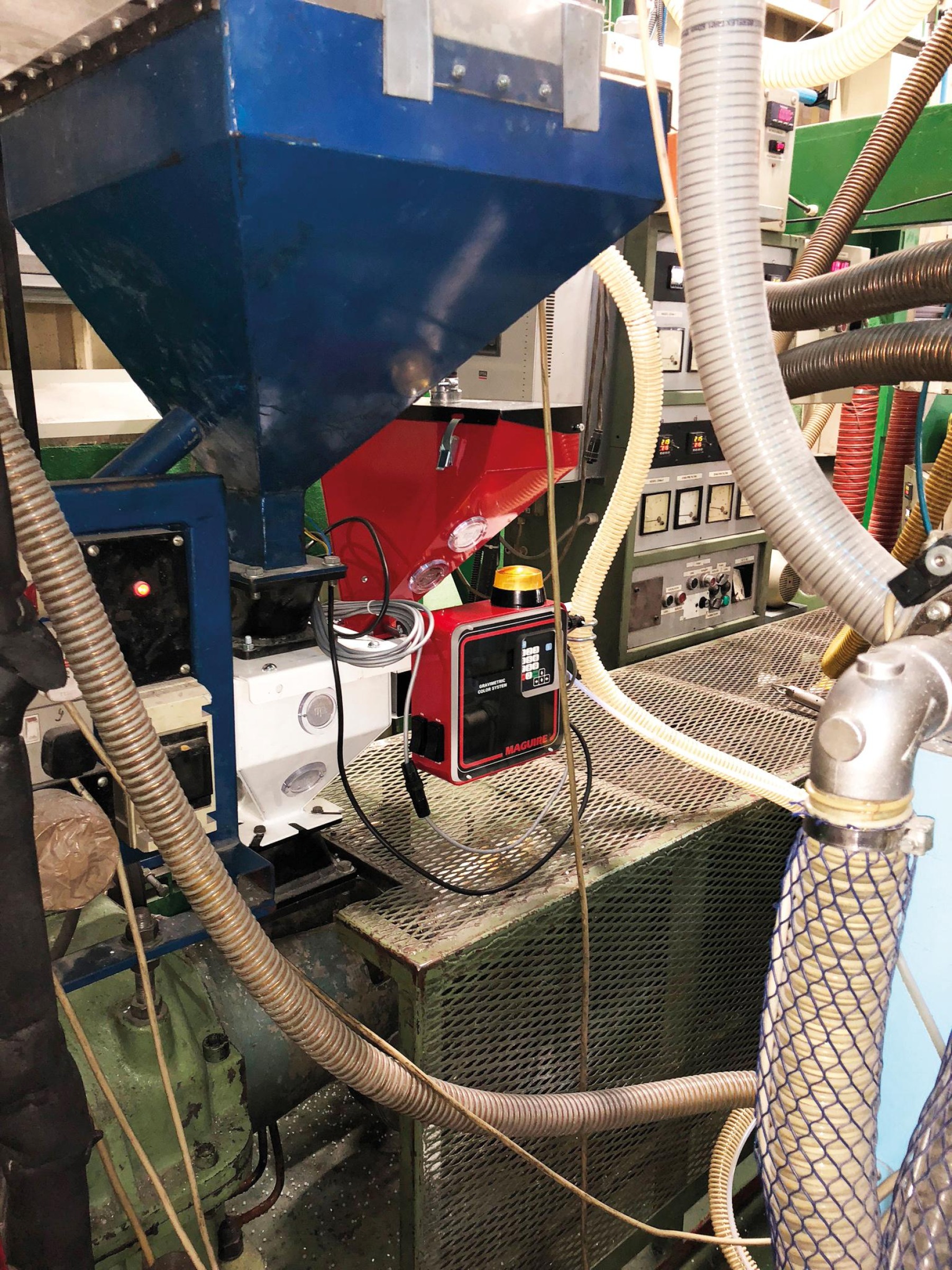

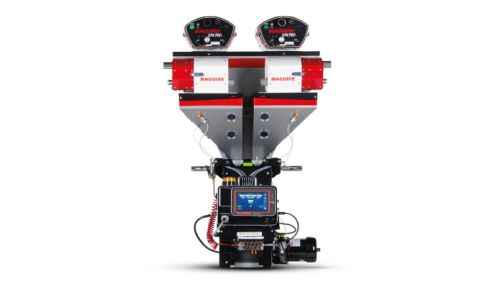

WSB Gravimetric Blenders

Control the flow of material and haul off speeds.

Process control.

Maguire offer Pipe and Profile extrusion processors complete raw materials handing solutions for blending, dosing, drying, and conveying.

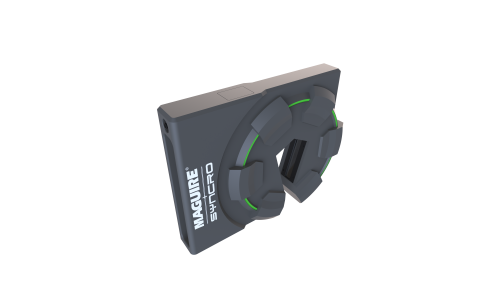

In addition, with the Maguire + Syncro partnership we provide modular and comprehensive upgrades for all types of mono and co-extrusion Pipe and Profile lines. From WXB Gravimetric Blending with integrated Extrusion Control, Gauging System upgrades, Surface Defect Monitoring, Diameter Monitoring and Control, and Inline and Offline Recycling to maintain primary value of scrap, and feed directly close-loop back to Gravimetric Blending systems.

With 30+ years of Pipe and Profile extrusion application experience, backed with thousands of installations globally, Maguire have supplied a diverse range of industries - from building, automotive, medical, and consumer goods, to furniture, agriculture, leisure, utilities, machinery, electronics and packaging.

Energy efficient vacuum drying method.

Faster drying, faster start-ups, significantly lower maintenance

Up to 10% material cost reduction from automatic gram/meter / micron regulation.

Automatically regulate extruder and haul-off speeds to always be on target.

Reduced start-up material waste & changeover scrap.

Recycle primary grade scrap into primary grade product directly.

Wide range of materials conveying solutions for small, medium and large applications.

Improve surface defects such as asprotrusions, throttling, abrasions, local insulation lack, partial detachments or flakes.

Non-contact measuring device for precise diameter control of pipes.

Automatic extruder & hauling control.

3x product types available suited to different diameter sizes.

Ideal for individual conveying applications for single and multiple material stations.

Easy and precise metering of liquid color & additives.

Energy efficient drying for small technical drying.

Clear-Vu™ receivers for easy visual status on loading.

Smart unloading for gaylords & octobins.

Volumetric feeders for granule, powder, regrind and liquid.

Transform purgings into high quality regrind.