| Option | Model | Description |

|

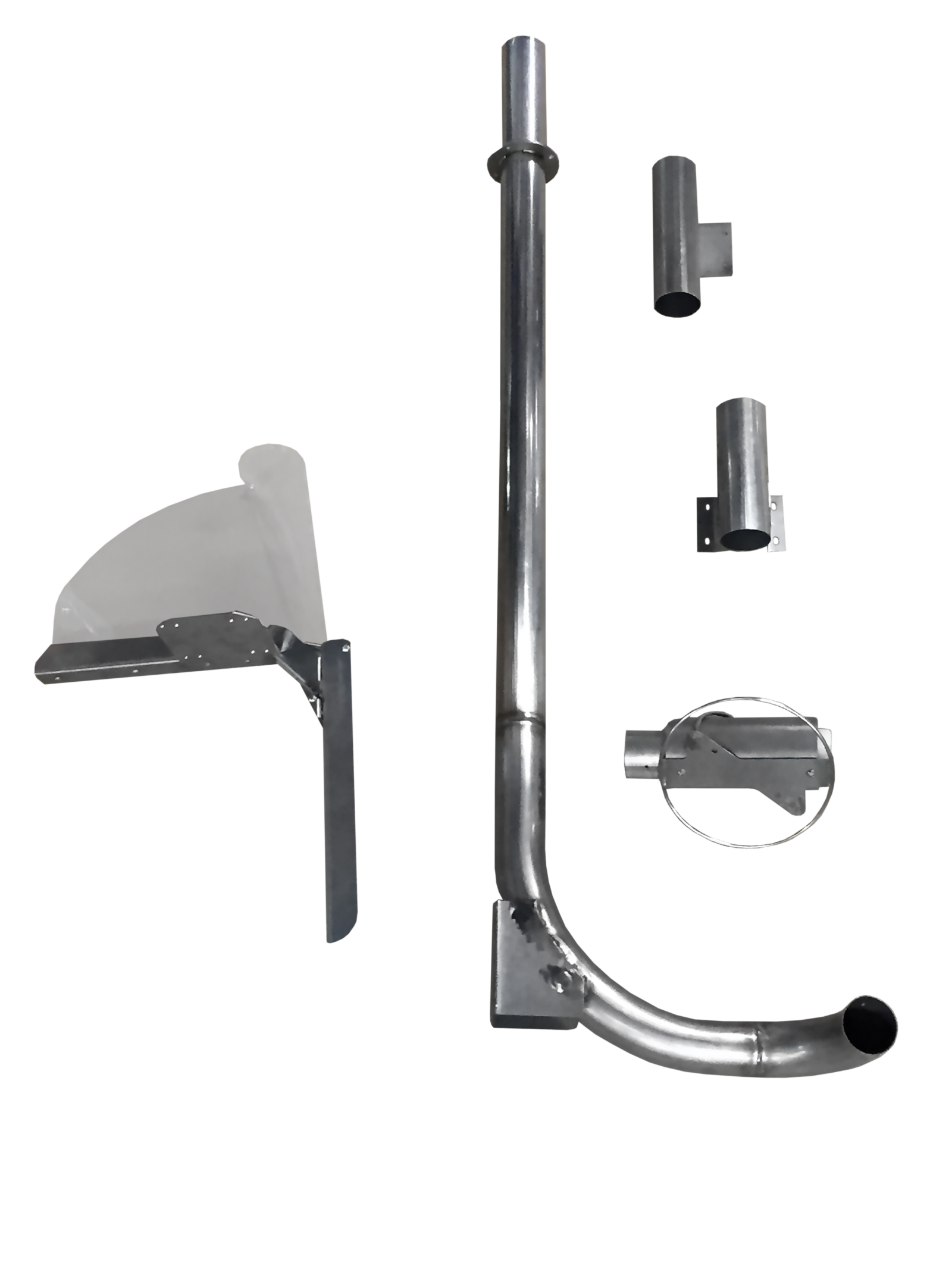

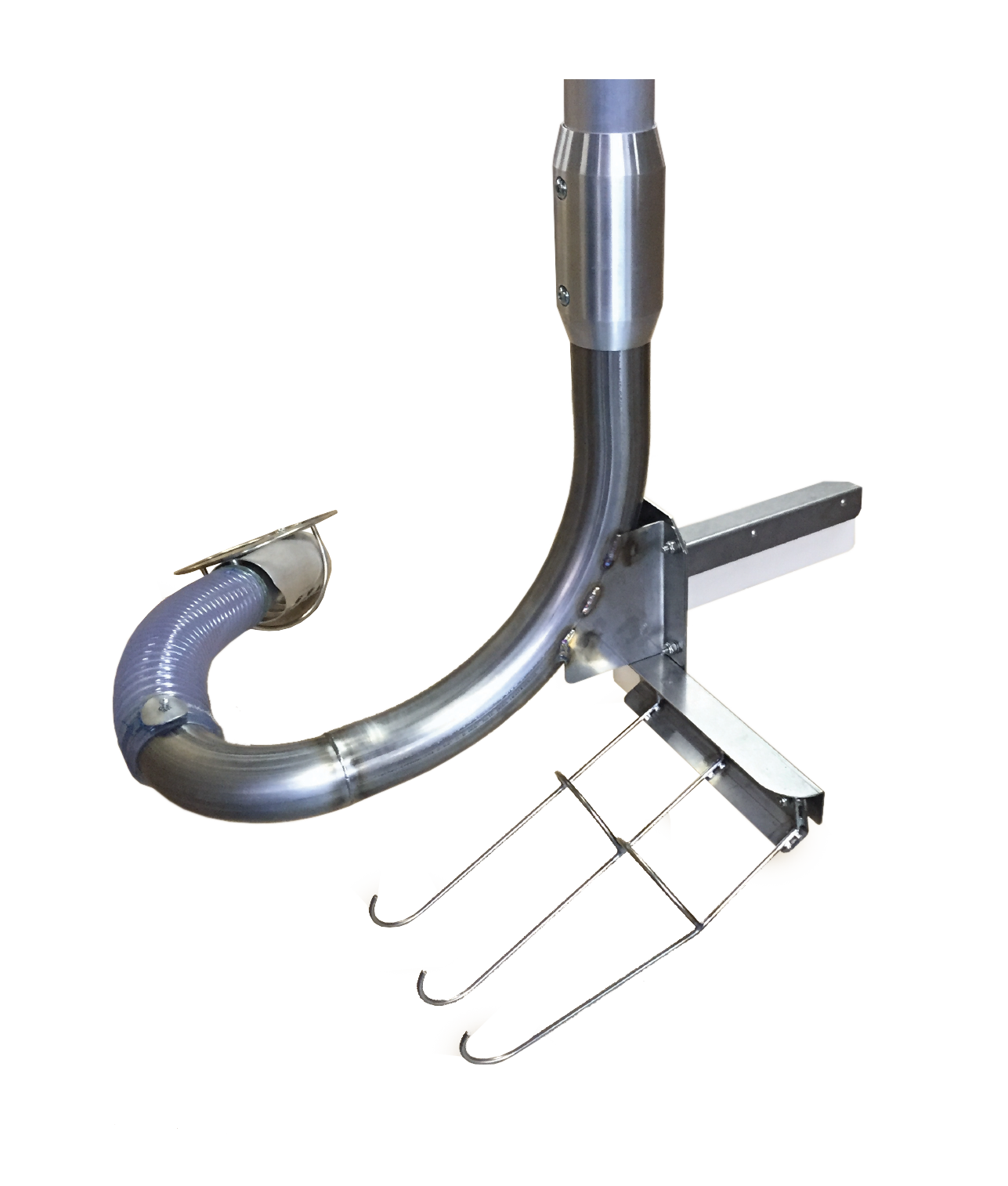

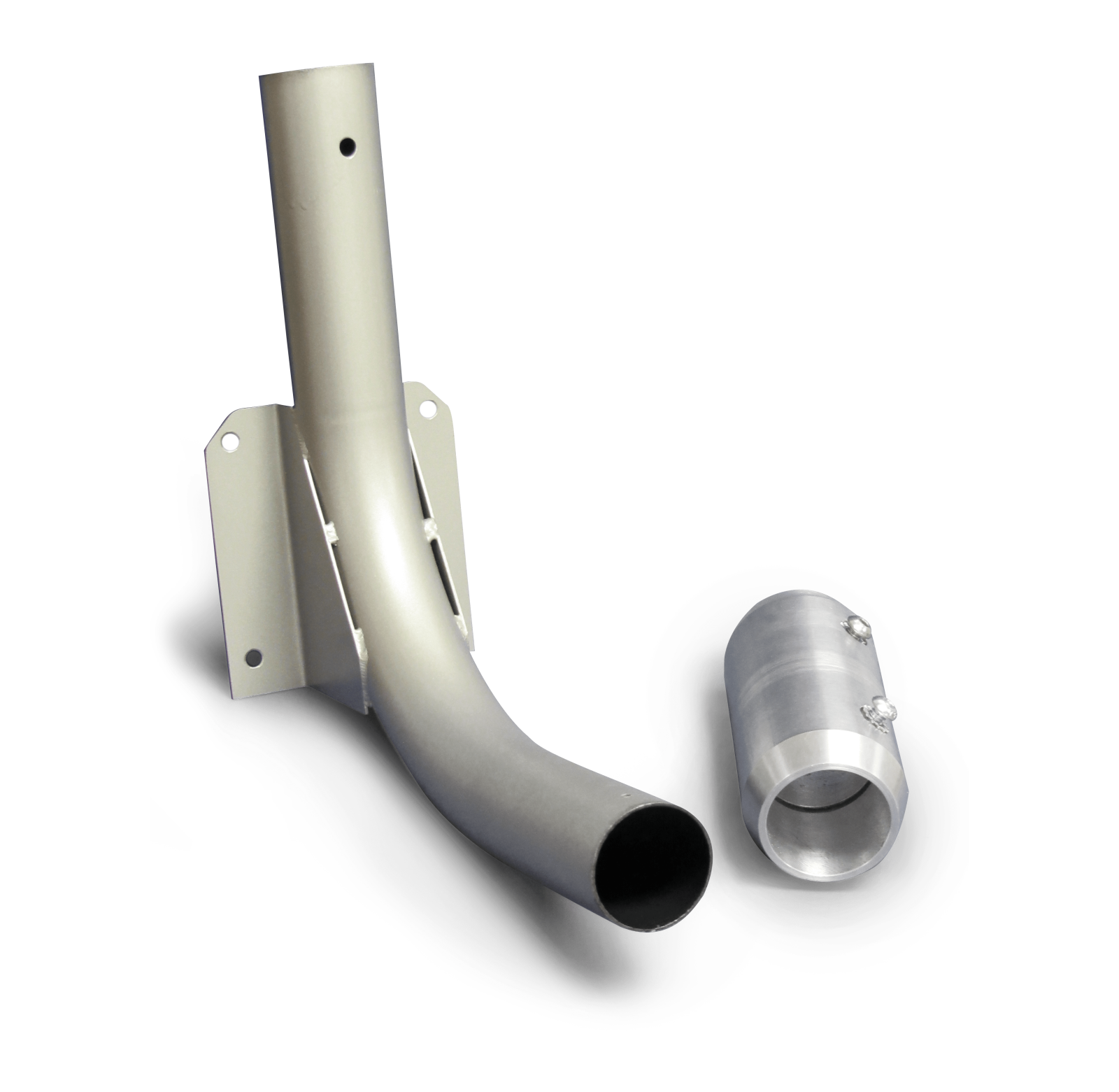

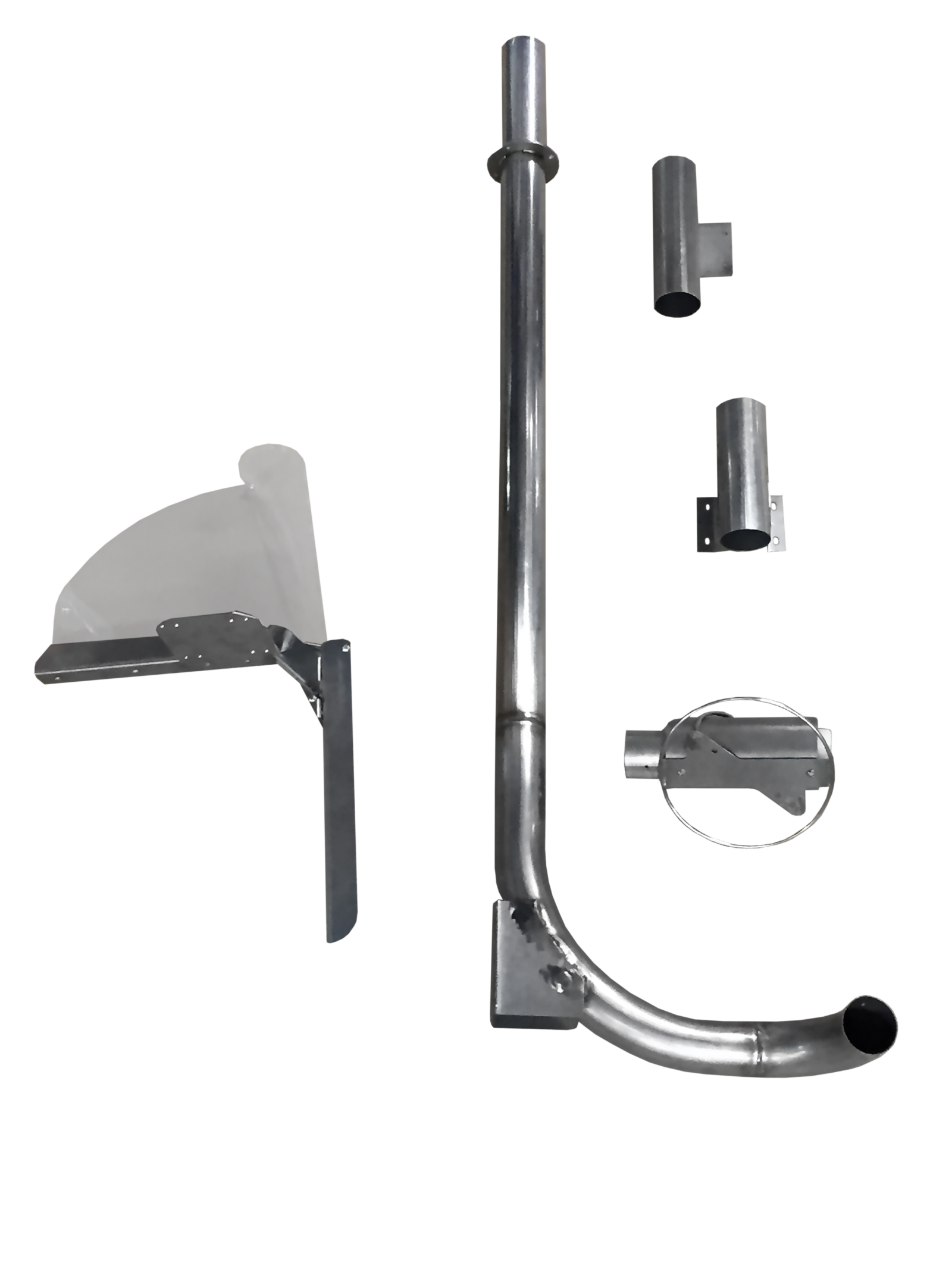

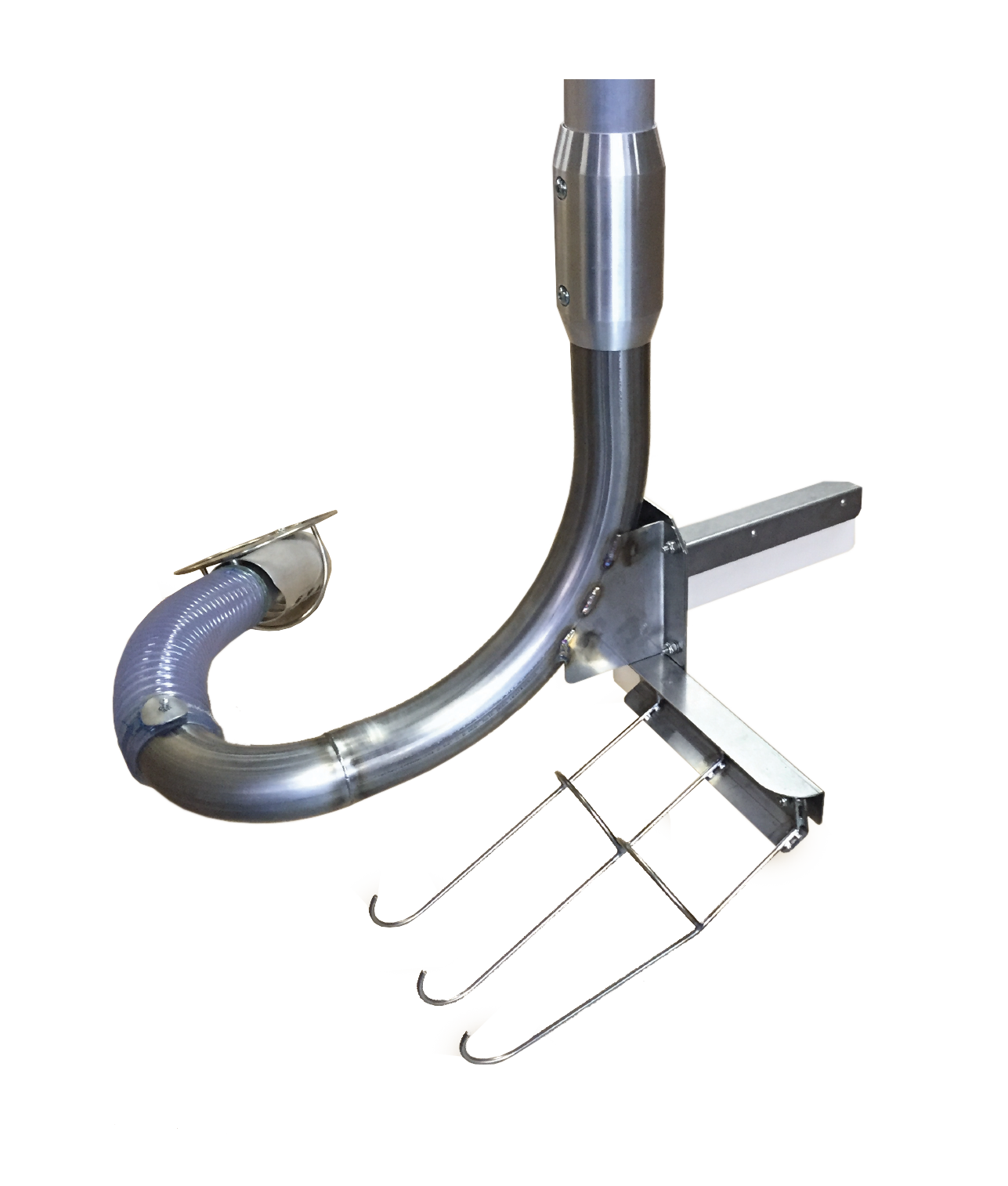

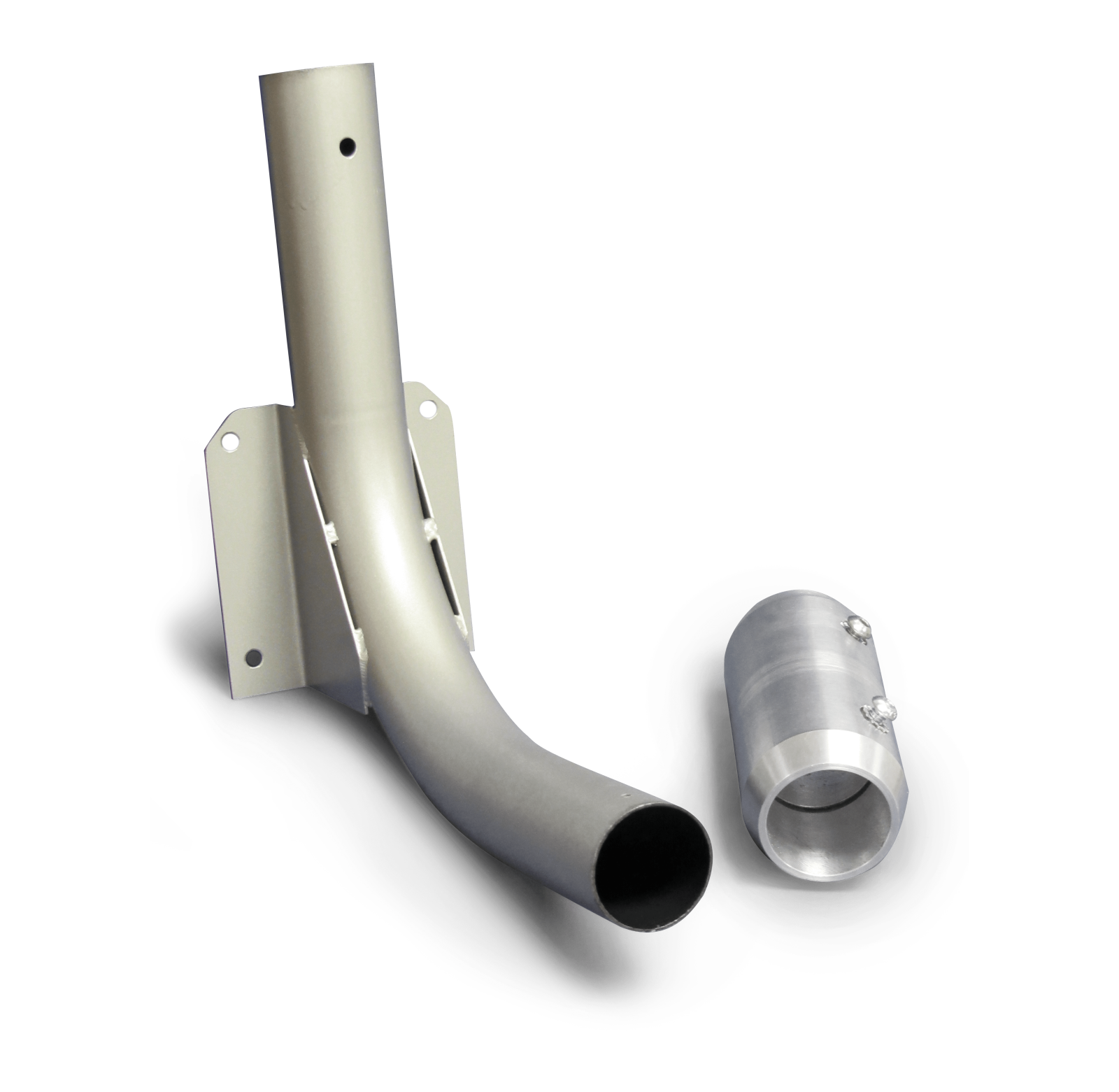

| Full Stainless Steel Sweeper Assembly: Brush arm assembly, J-Tube assembly, Wand pick-up assembly, Upper welded connector, Upper tube connector. | SW-48 | This option replaces all aluminum parts that are in contact with material, with stainless steel parts. Available for standard Sweeper sizes. |  |

| Full Stainless Steel Sweeper Assembly (Tall): Brush arm assembly, Wand pick-up assembly, Upper welded connector,Tube Extension, Coupler, Vac tube upper weldment. | SW-84 | This option replaces all aluminum parts that are in contact with material, with stainless steel parts. Available for tall Sweeper sizes. |  |

| Stainless Steel Brush Assembly | SW-48, SW-84 | This assembly is a direct replacement for the standard steel parts. |  |

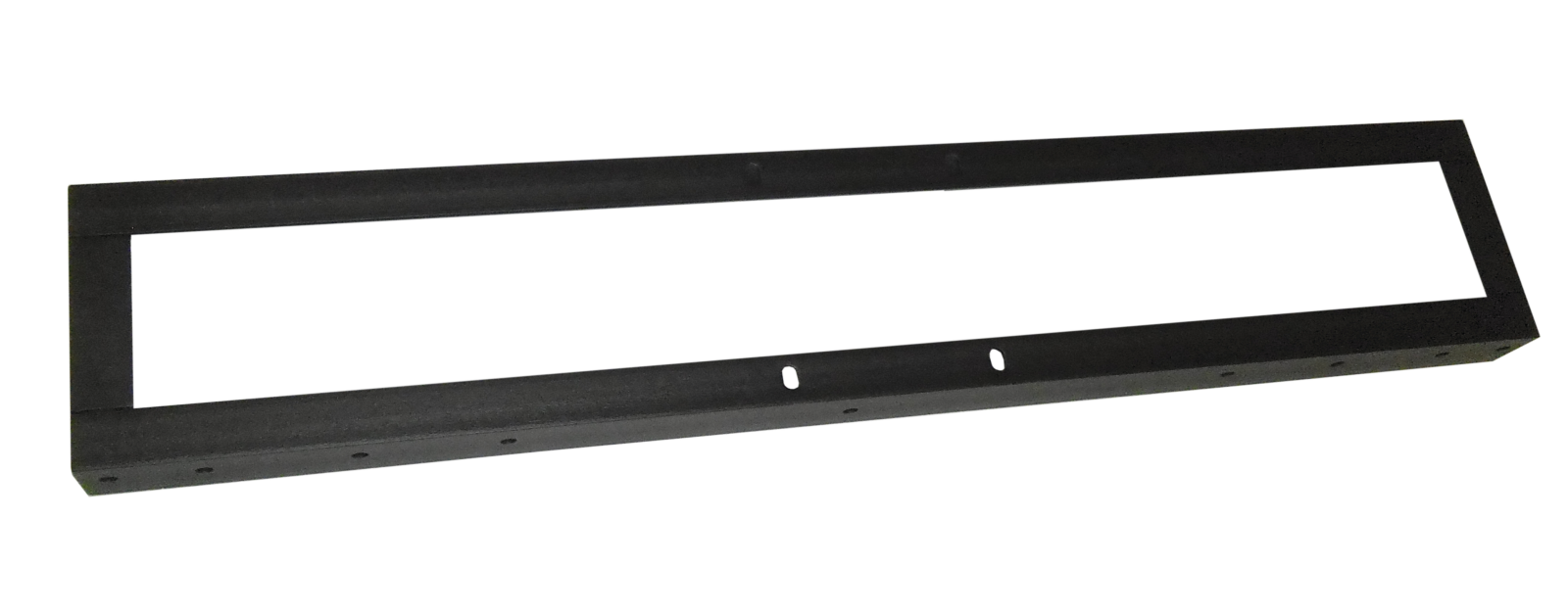

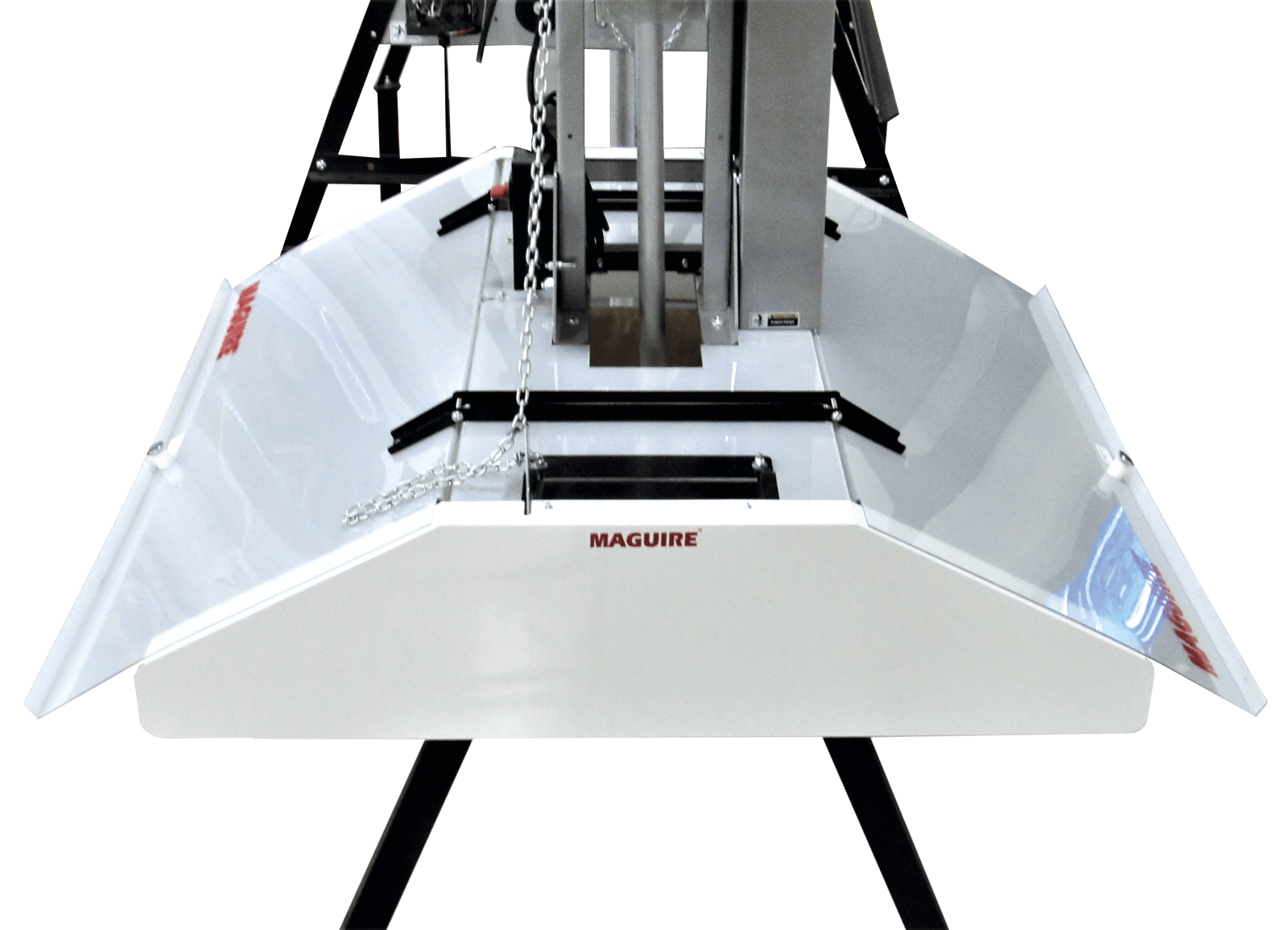

| Wider Gaylord Stand Top* | SW-48, SW-84 | This option increases the width of the Sweeper stand assembly, to allow for more room to slide gaylord box under assembly.

*Frame is 6" wider. |  |

| Relocate Power Switch | SW-48, SW-84 | This option relocates the power switch from the far side of the Sweeper assembly to the gaylord box side of frame. |  |

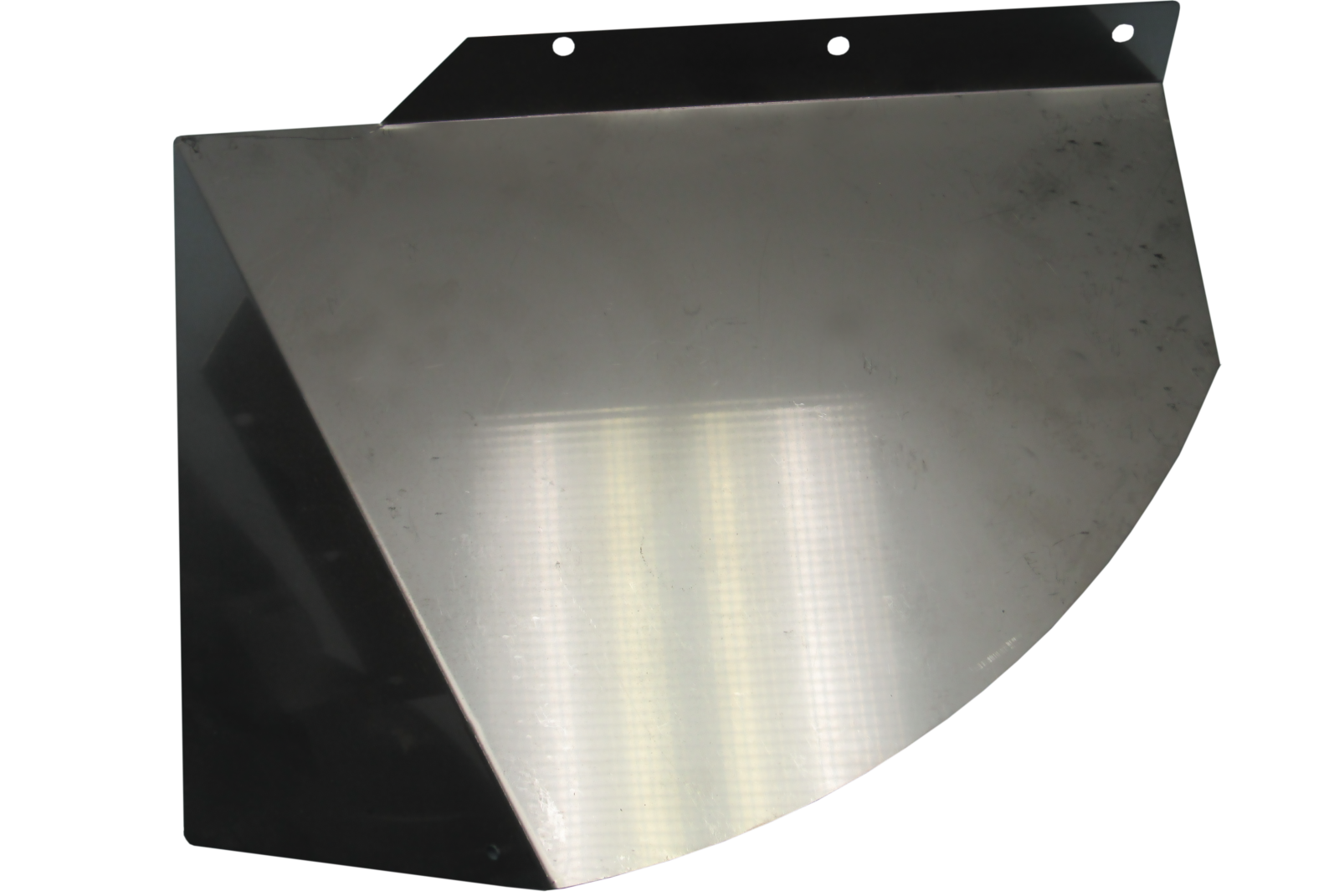

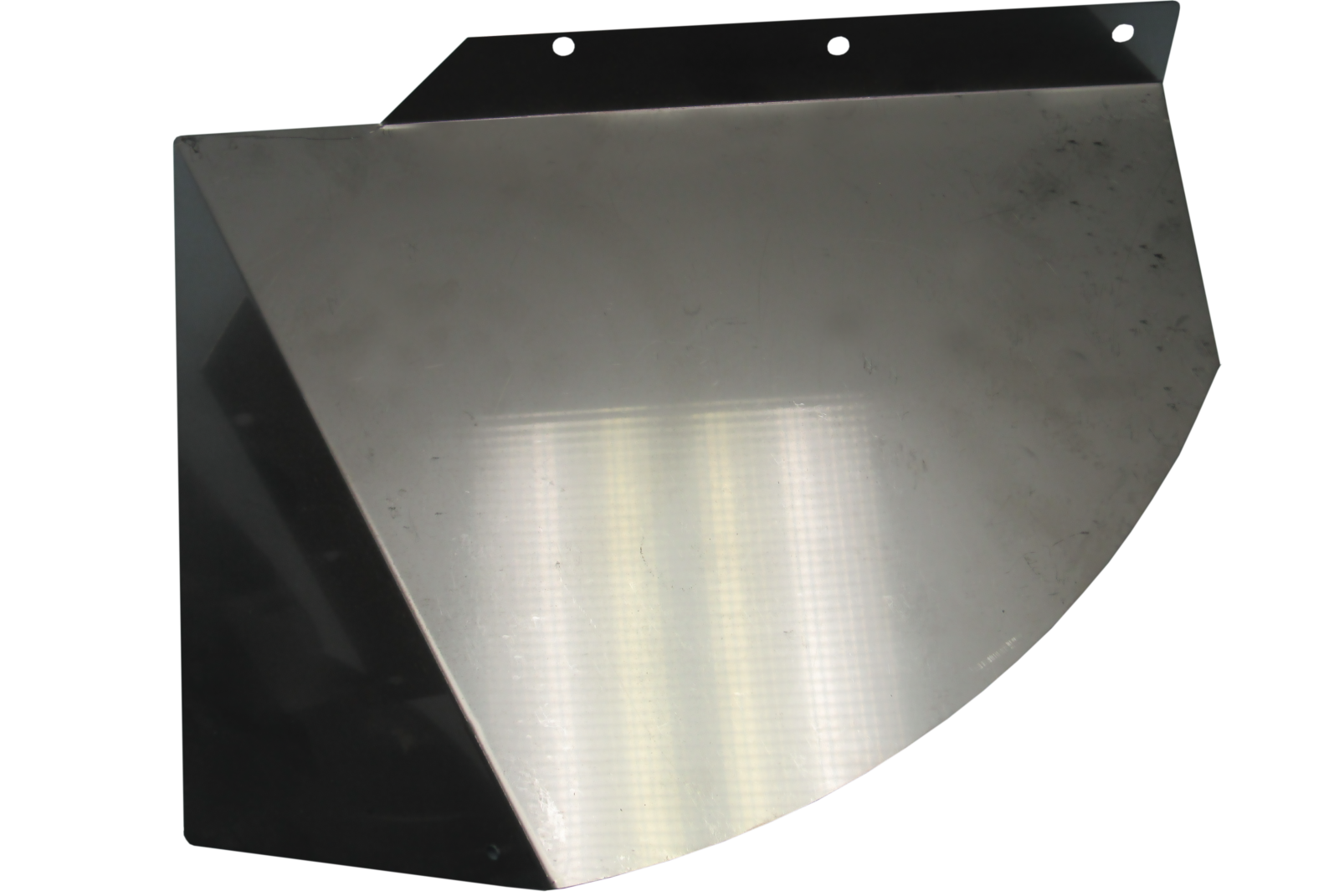

| Stainless Steel Sweep (Bolt-On) | SW-48, SW-84 | For highly abrasive materials conveying and special applications requiring a hardened surface finish. |  |

| Wiper Blades (FDA) | SW-48, SW-84 | These two pieces are made from 1/16" thick approved Nylon (FDA compliant). Direct replacement of the two assembly brush assemblies. |  |

| Stainless Steel Tines | SW-48, SW-84 | Good for poor flowing or sticky materials to assist with consistent material movement. |  |

| Porcelain Lined Sweep (Parts) | SW-48, SW-84 | This part is very useful for abrasive material conveying applications. This part will replace the sweep to the lower portion of the J-Tube. |  |

| Porcelain Lined Sweep | SW-48, SW-84 | These parts are very useful for abrasive material conveying applications. This option will install a porcelain lined sweep to the lower portion of the J-Tube. |  |

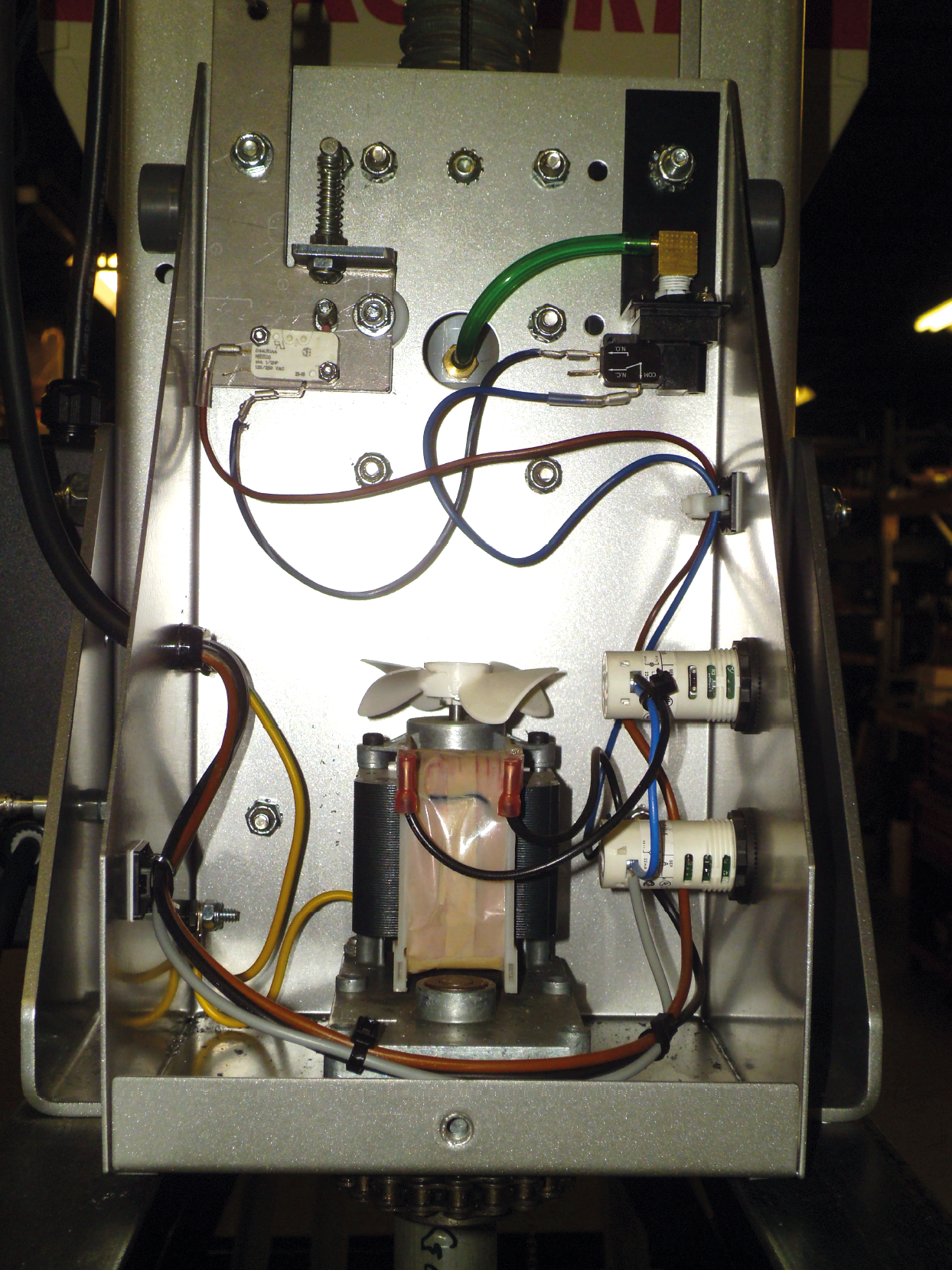

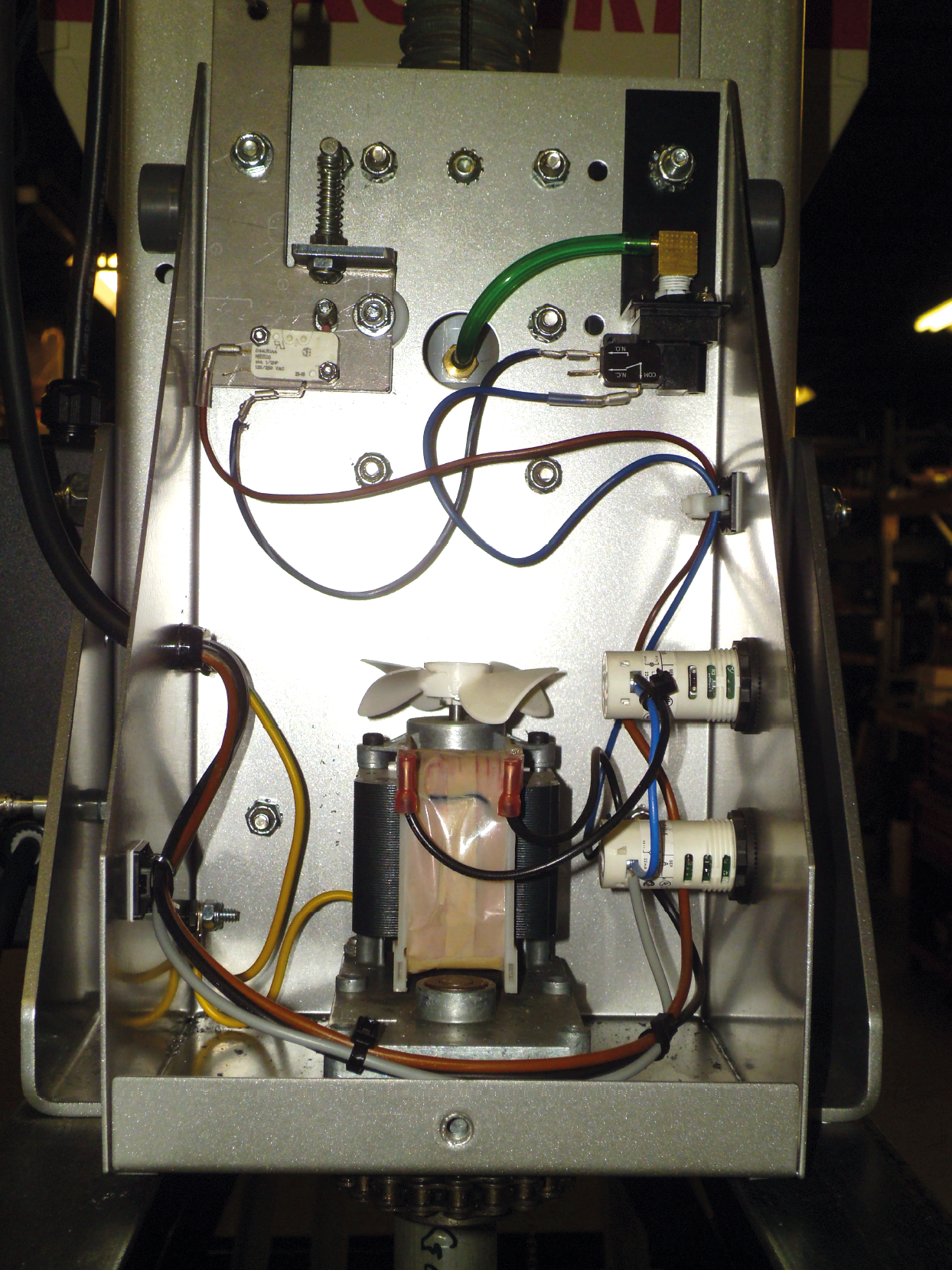

| Sweeper Motor Disconnect Switch | SW-48, SW-84 | Automatically turns off gear motor as trolley is raised. To prevent motor from turning if assembly is lifted. |  |

| Stand Leg Extensions* | SW-48, SW-84 | Raise the Sweeper frame 4" above ground floor. Additional height spacers to provide additional height for different sized material container.

*4 steel legs included. |  |

| Wheel Stand Kit* | SW-48, SW-84 | Mobilizes the Sweeper stand to allow for local re-positioning around material containers and increase accessibility.

*Set of wheels attached to sweeper stand. |  |

| Cloth Material Bin Cover | SW-48, SW-84 | Stretched over material container. Fabric container cover with clear viewing panels placed on material container - allows easy view but stops foreign bodies entering material container. |  |

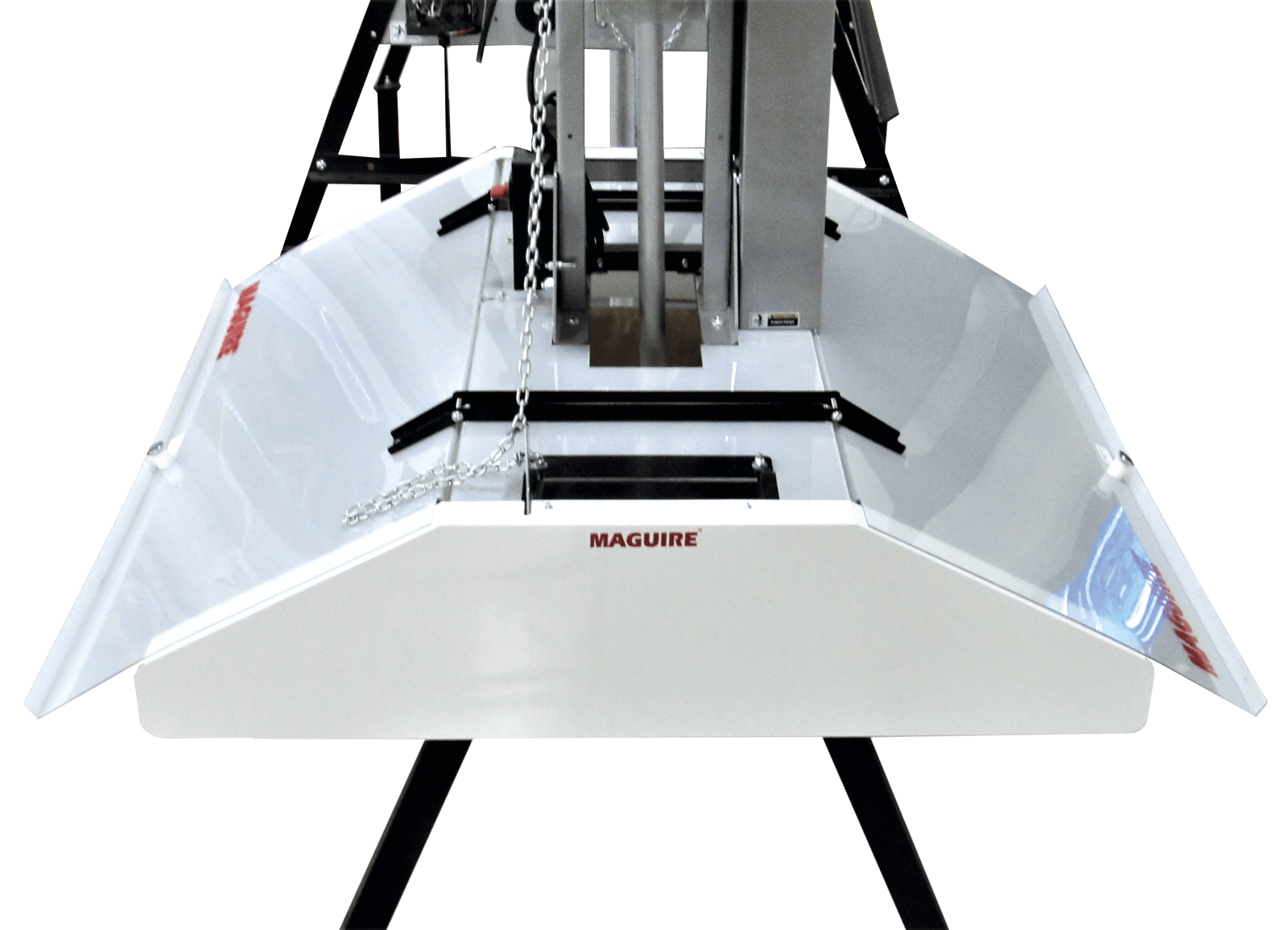

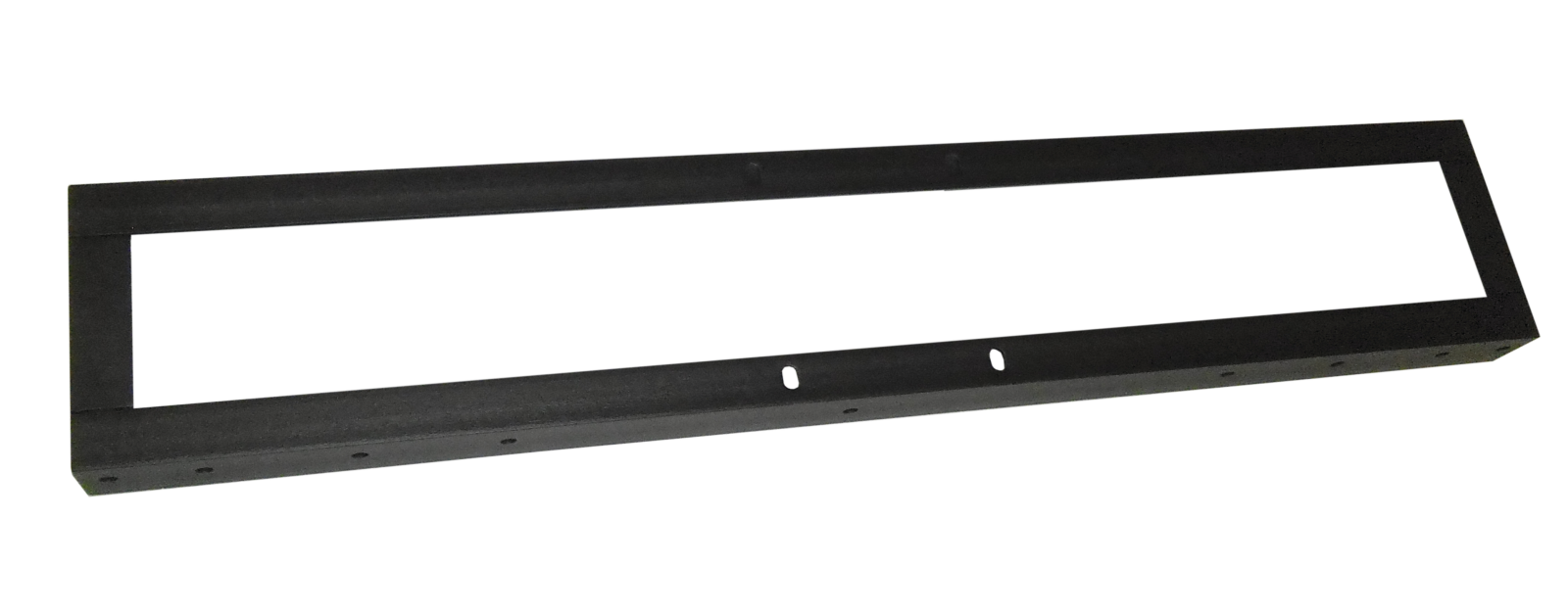

| Clear Lexan Material Bin Cover | SW-48, SW-84 | Gaylord cover that is mounted to the Sweeper stand assembly. This in turn will help foreign material from accidentally falling into the gaylord production material. The two hinged cover allow for easy access to the material container. It is a simple assembly with standard hand tools, and the Sweeper assembly does not need to be removed from the stand. |  |

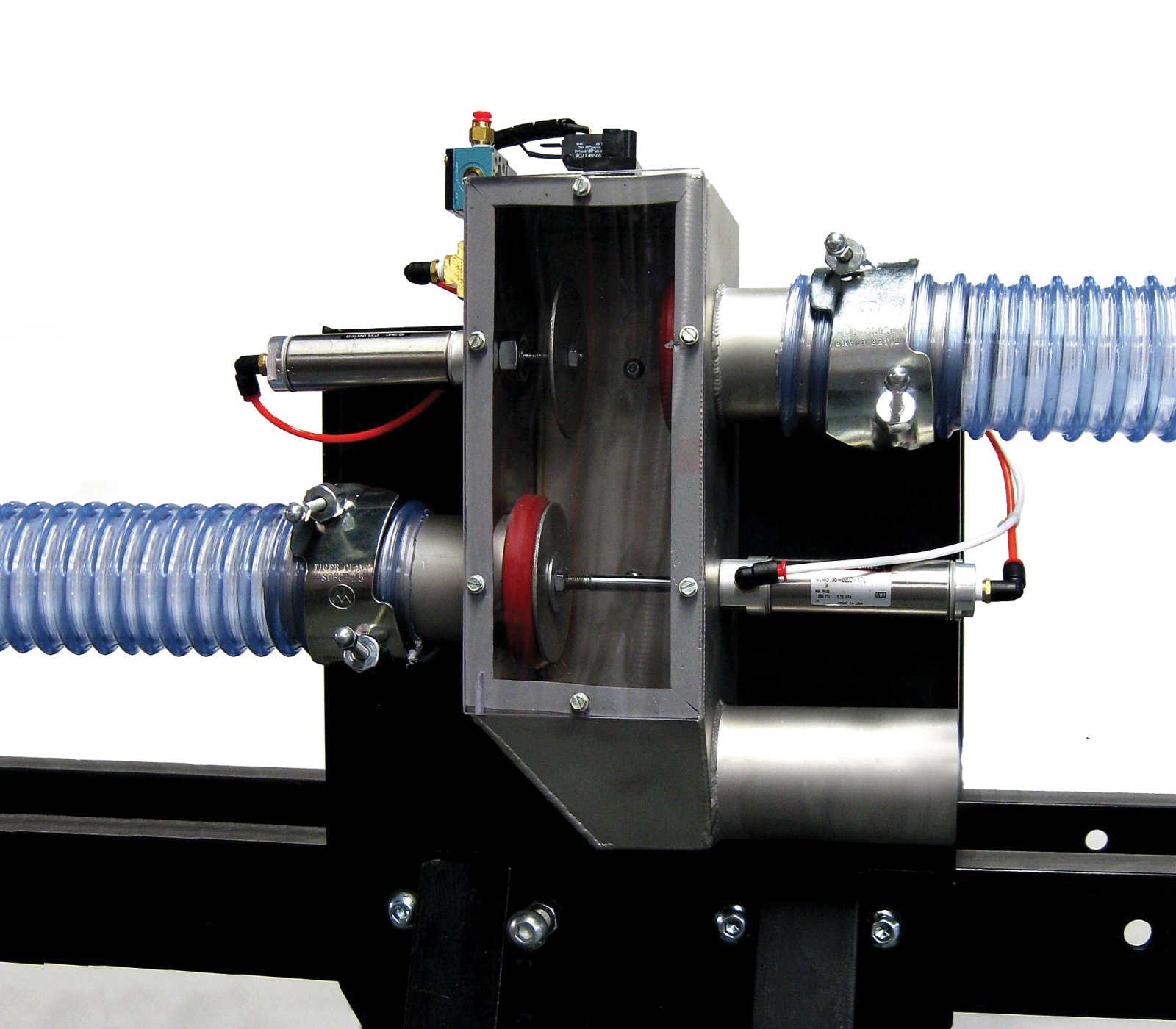

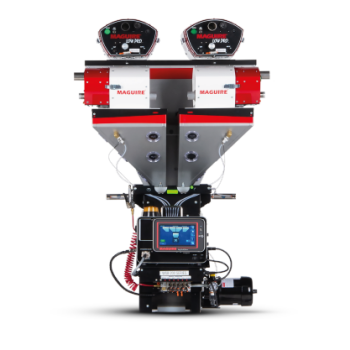

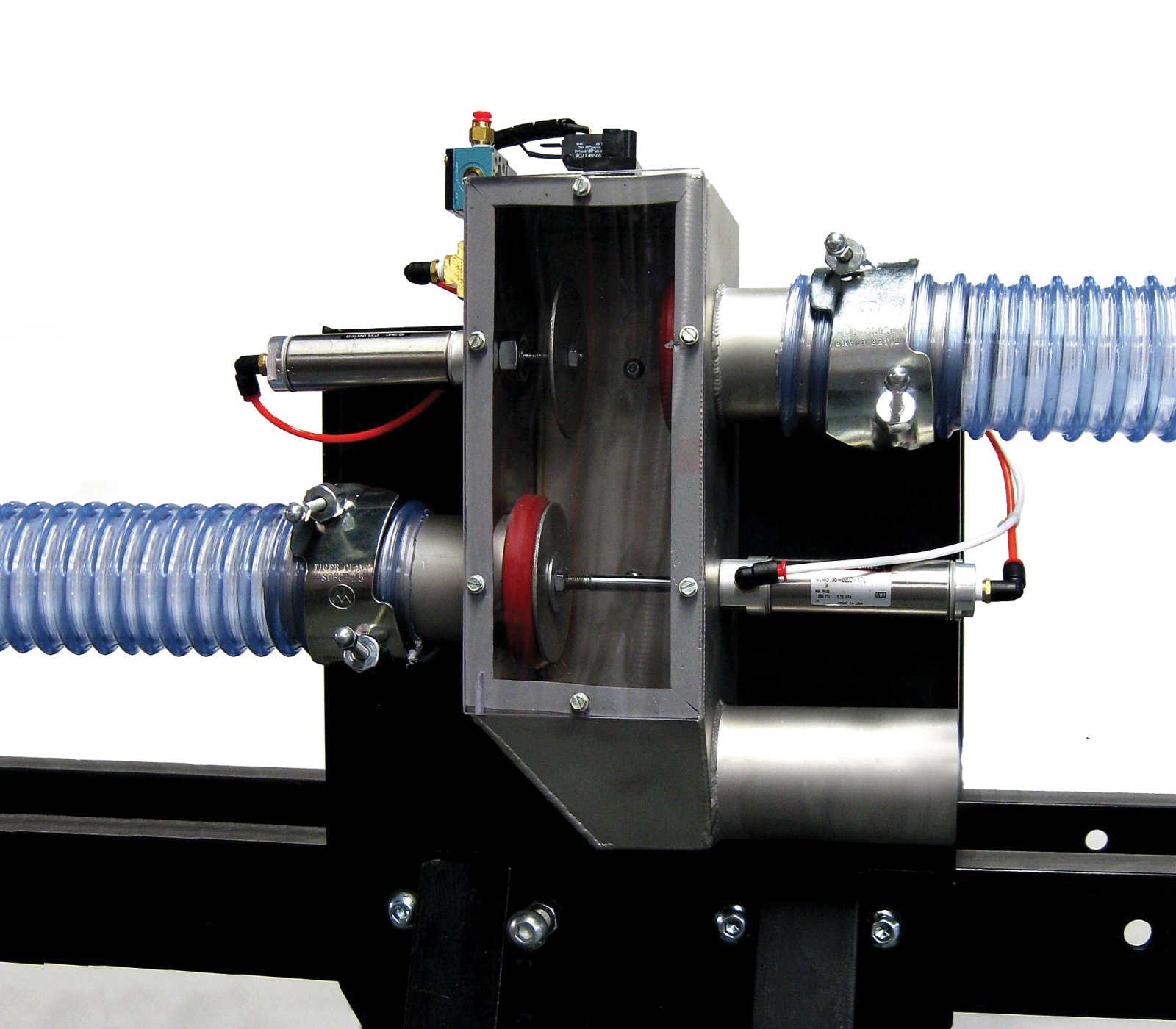

| GHL Loader Series | SW-48, SW-84 | Combine with the GHL Loader Series for a complete material container unloading package. |  |

| Low Level Alarm | SW-48, SW-84 | This option will allow a low level sensor to be installed on the Sweeper unit. It is adjustable for a low level of the material in the material container. The control box has an audible alarm, and a strobe light to signal the level of material in the gaylord. |  |

| Dual Sweeper Control | SW-48, SW-84 | Interconnected controls for Dual Sweeper installations. Automatic switch-over from material controller A to container B - allows for longer duration without manual intervention. |  |

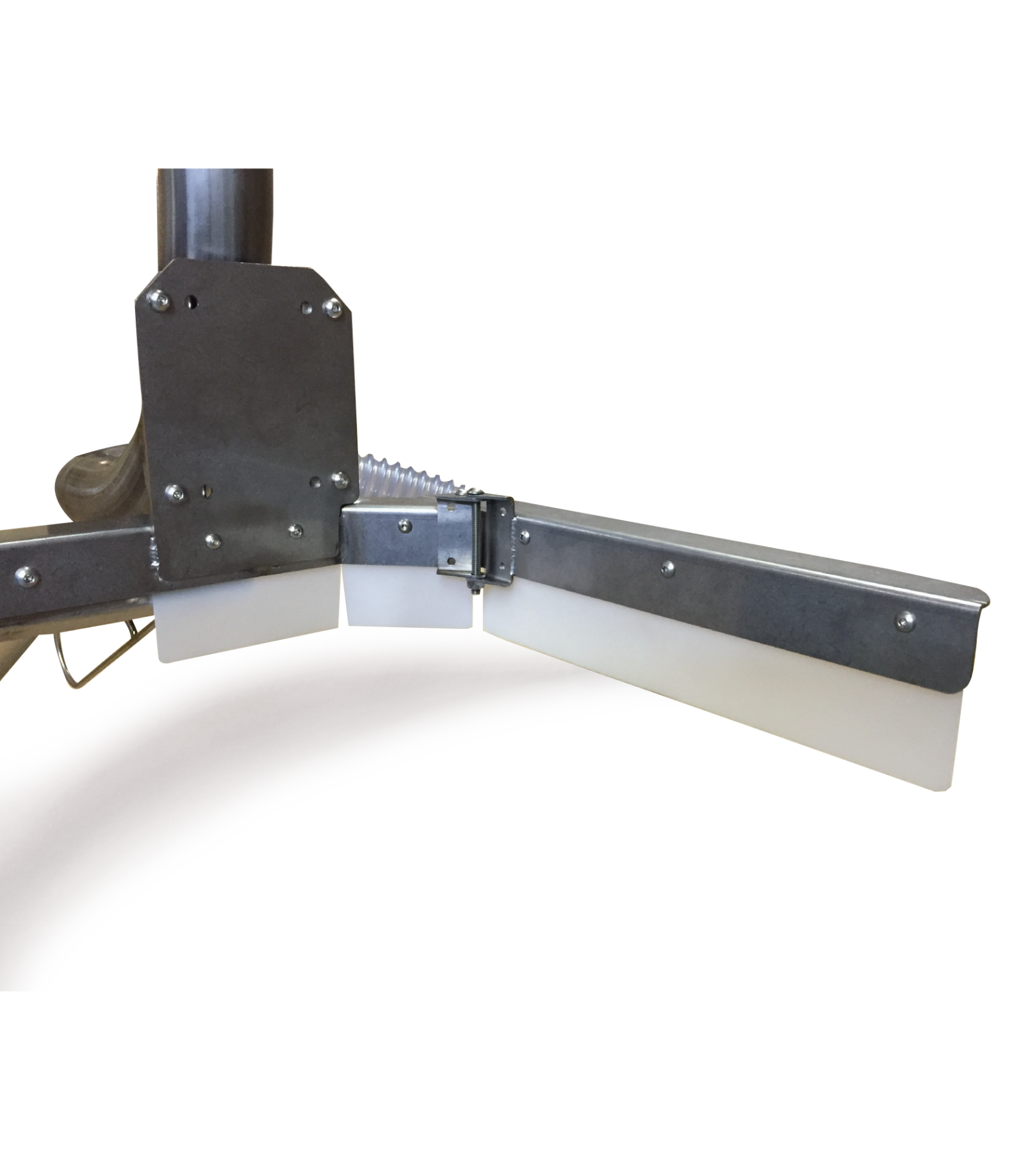

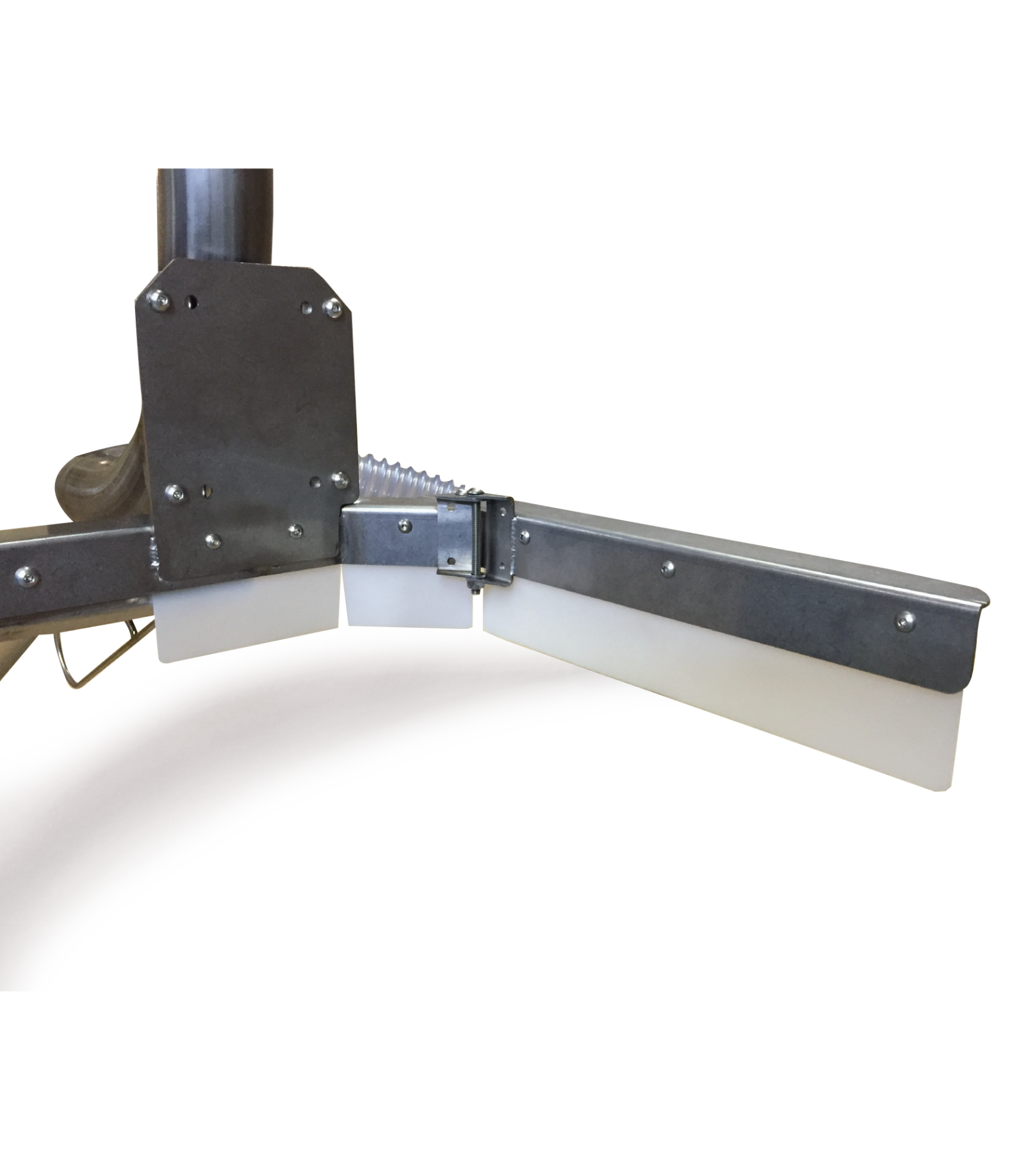

Sweeper Gaylord Blades:

Nylon, Stainless steel and thick Lexan blades. | SW-48, SW-84 | Used to allow the Sweeper to slide along the top of the material and not bury itself (Example: Food or medical grade materials). |   |