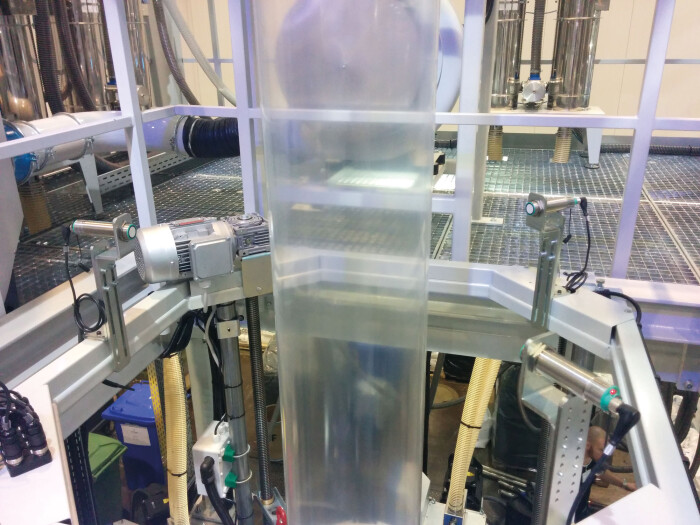

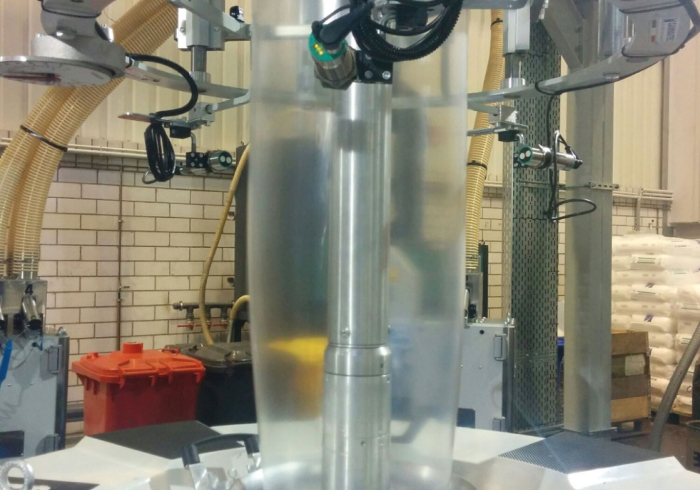

Another critical factor on from materials blend and extrusion control for the performance of a blown film line is the IBC (Internal Bubble Cooling), with integrated auto width control for the layflat.

Upgrading a line without IBC & Layflat Control, or a line with a dated simpler system can deliver significant performance benefits for any blown film line.

Maguire + Syncro offer SYibc, which is a convenient and effective package for IBC and automatic Layflat Control. A processor can upgrade as a standalone product or integrated as part of the program of modular upgrades for improving performance on a blown film line from Maguire + Syncro range of products.

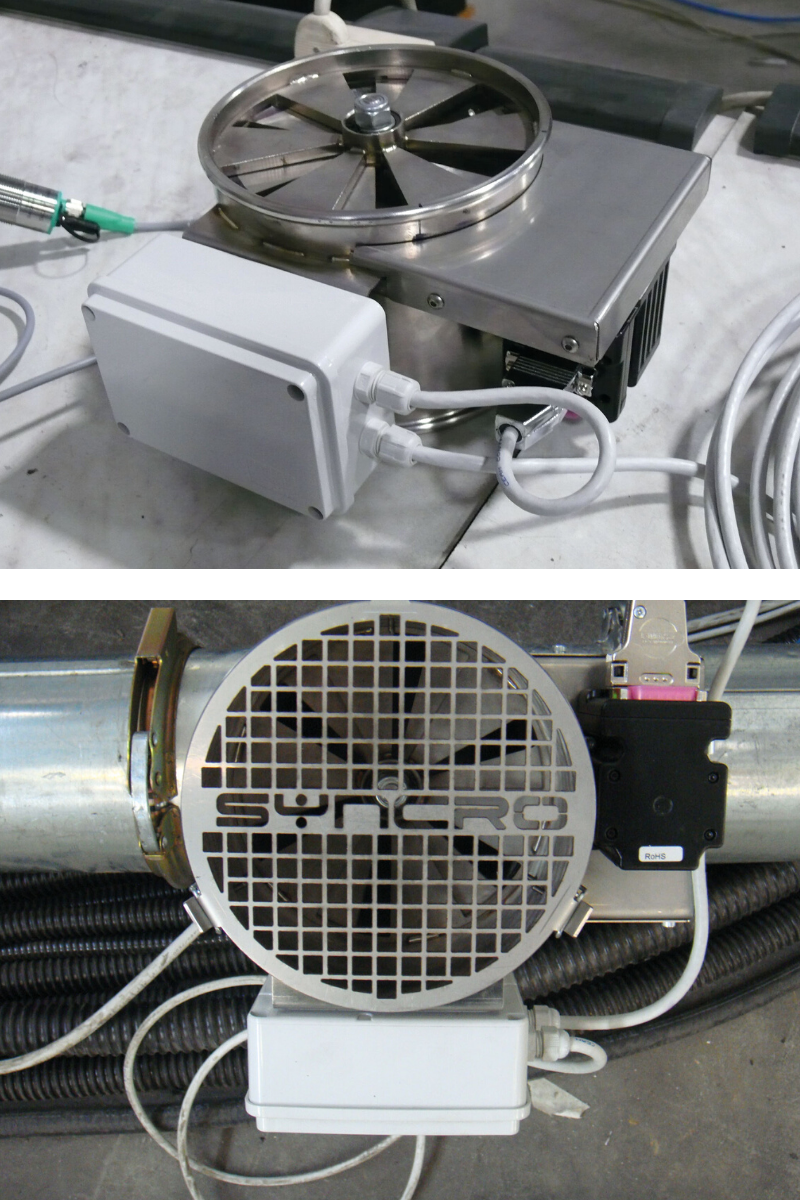

To enable fast and accurate control of a layflat width the SYibc uses a triangulation of 3 non-contact ultrasonic sensors, with a separate calibration sensor to moderate for ambient conditions. This data provides constant readings to the IBC PLC control, and enables the IBC stepper-controlled valves to be precisely regulated for fast and consistent control of the internal bubble cooling airflow.