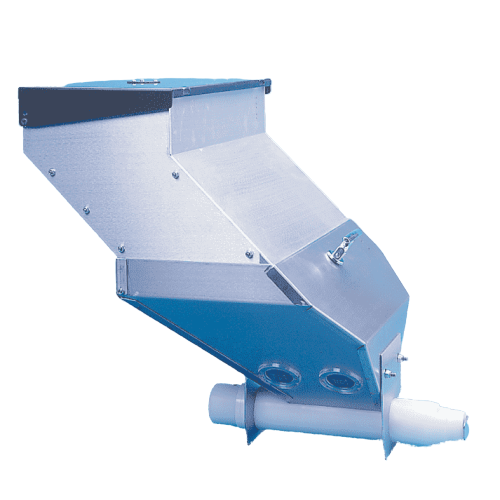

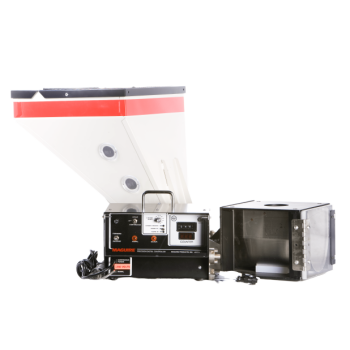

Removable Stainless Steel Hopper

- Hopper capacity restricted to 0.5 cubic foot (14 L) which is about 10 pounds (4.5 kg).

- The restricted capacity design avoids compaction of powders and helps ensures consistent metering.

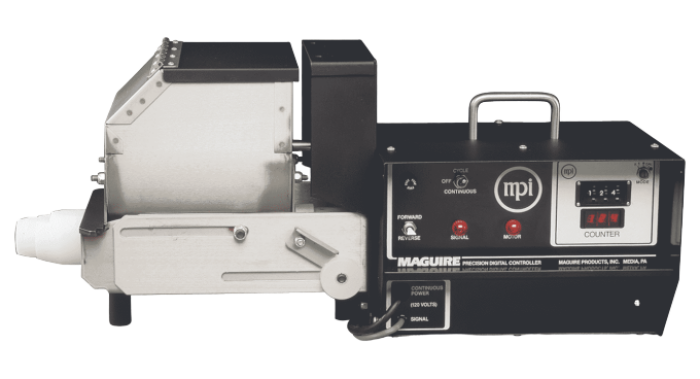

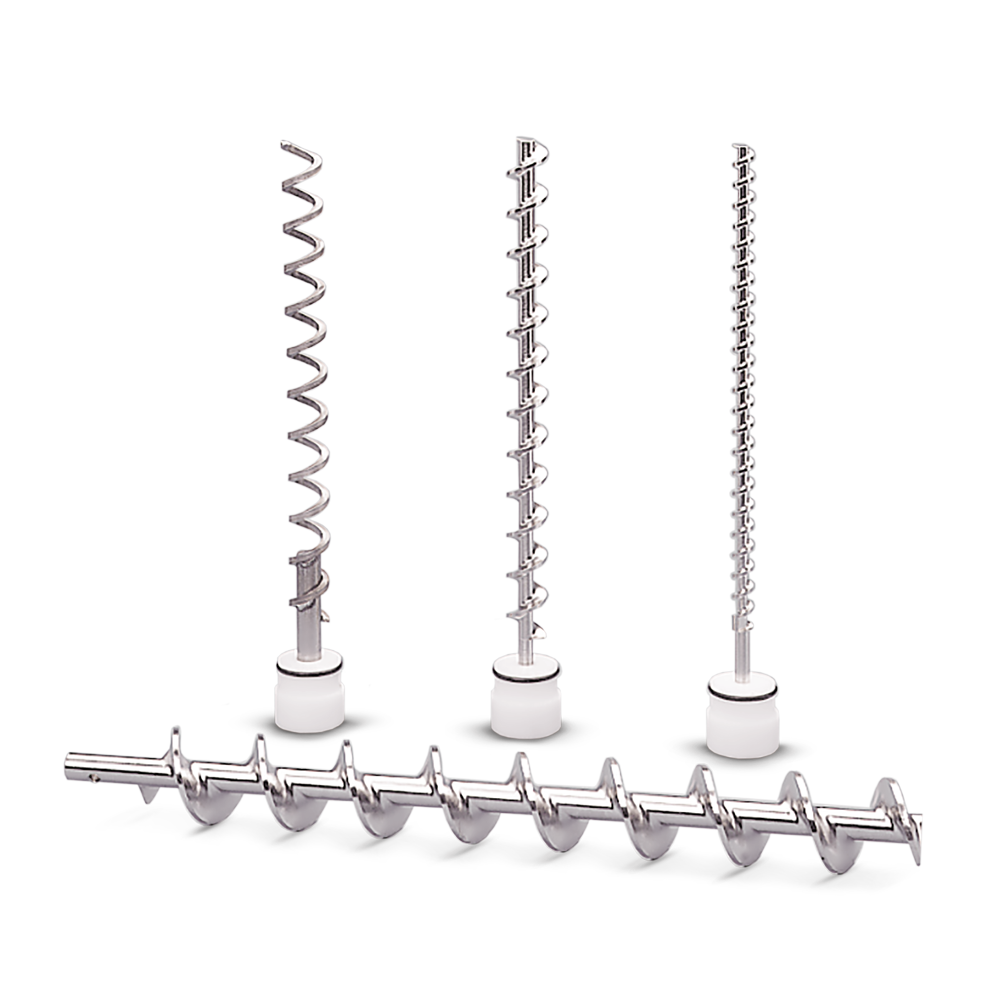

Spiral Dosing Auger

- The powder feeder uses a spiral screw to assist with powder dosing.

- Choice of spiral screws and motors according to settings and throughputs.