Control Regrind Usage

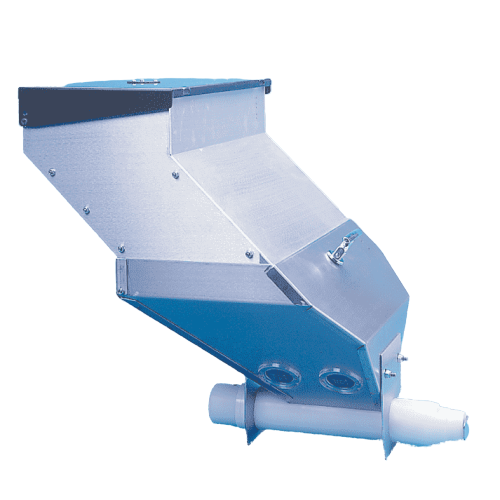

- Installed beneath existing material hoppers.

- Easily and accurately use previously colored regrind while avoiding double-coloring.

- Regrind enters the flow of resin at the same height as the color feed.

Compact receiver for accurate control of regrind usage.

Control Regrind Usage

See-Through Baffle Chamber

Select % Regrind Directly to Avoid “Double Coloring”

Quick Clean Out and Material Changes

Software and hardware controls regrind effectively.

Quick emptying of the hopper using a hinged clean out chute located directly under the feed screw and hopper.

Accurately maximize regrind consumption and minimize color if color already present in regrind.

Removable acrylic windows provide clear view of resin and color flow, plus easy access to baffle chamber.

| Model | Auger Size | Max RPMs | Continuous Output lb/hr | Dispense | |

| Min | Max | (One Cycle) | |||

| MRF-8-34 | 1" (25 mm) | 55 | 1.8 (82 gm) | 58 (26.4 kg) | 0.05 cc |

| MRF-8-50 | 1" (25 mm) | 100 | 2.7 (1.2 kg) | 105 (47.7 kg) | 0.08 cc |

| MRF-16-50 | 2" (50 mm) | 100 | 5.3 (2.4 kg) | 533 (242.3 kg) | 0.4 cc |

| MRF-16-94 | 2" (50 mm) | 188 | 10 (4.5 kg) | 1000 (445.5kg) | 0.8 cc |

| MRF-16-160 | 2" (50mm) | 320 | 17 (7.7 kg) | 1700 (772.7 kg) | 1.3 cc |

| Option | Model | Description | |

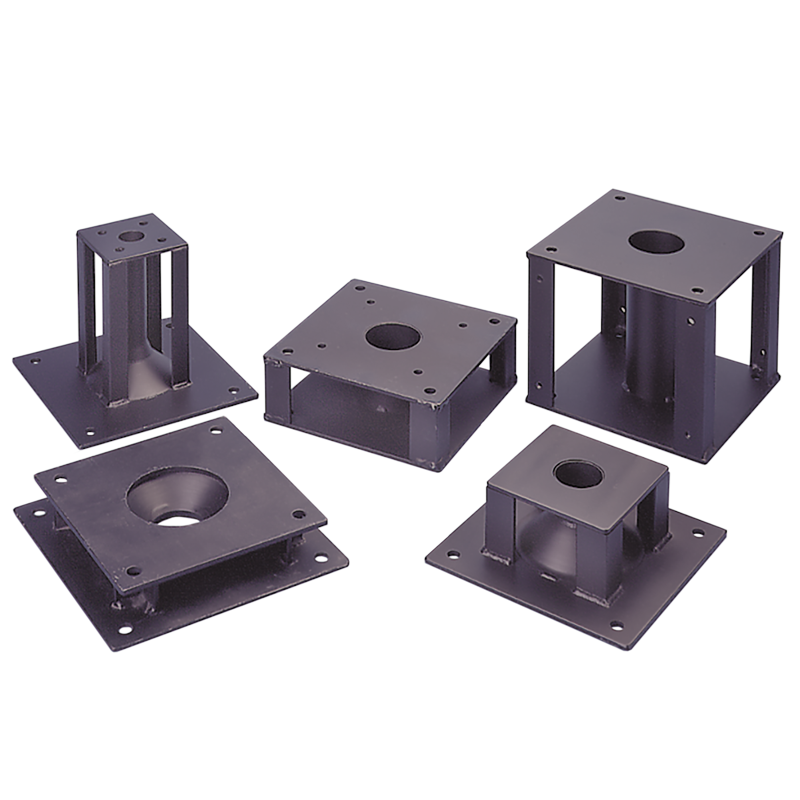

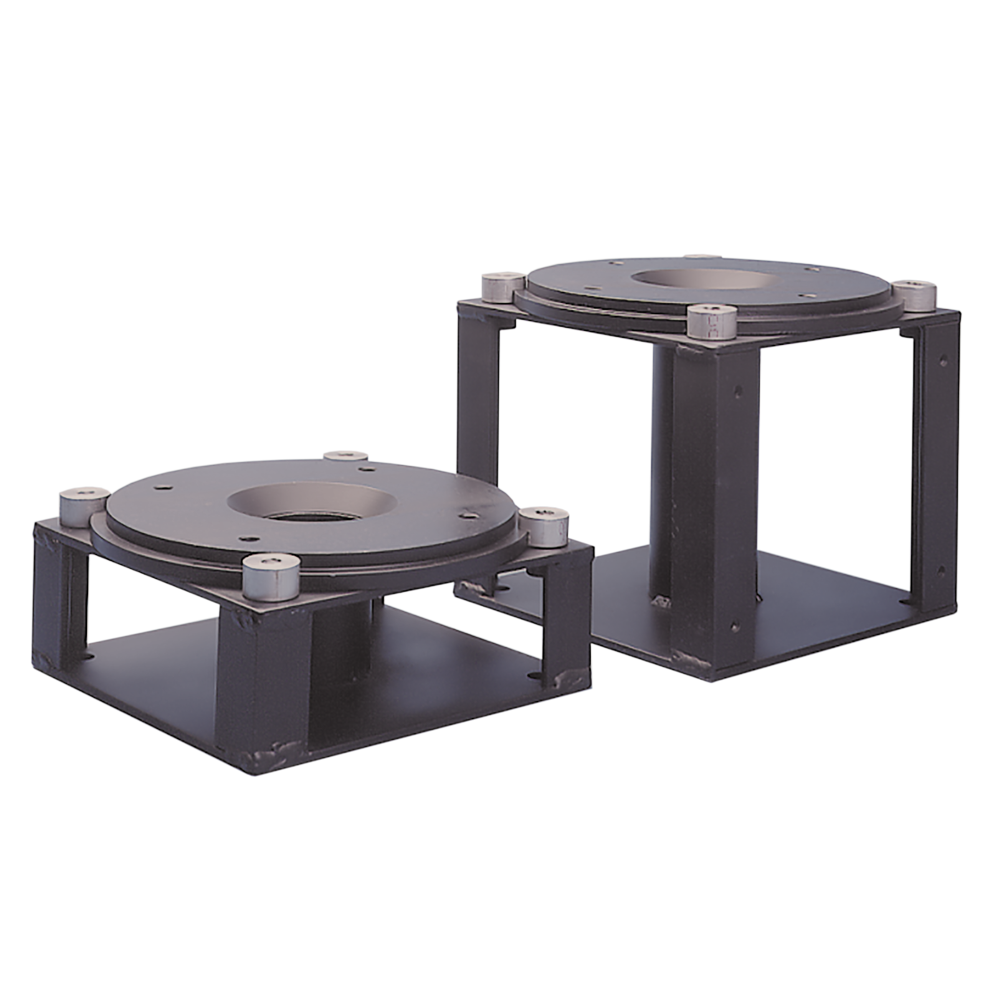

| Spacer Frames | MRF-8, MRF-16 | Raise feeders above the feed throat of the process machine. To improve access & material change over times. |  |

| Swivel Plates | MRF-8, MRF-16 | Allow for easy re-positioning of auger feeder & full rotation of the feeder to any position required. |  |

| Hopper Extensions | MRF-8, MRF-16 | Range of hopper extension sizes for different models to increase storage capacity. |  |

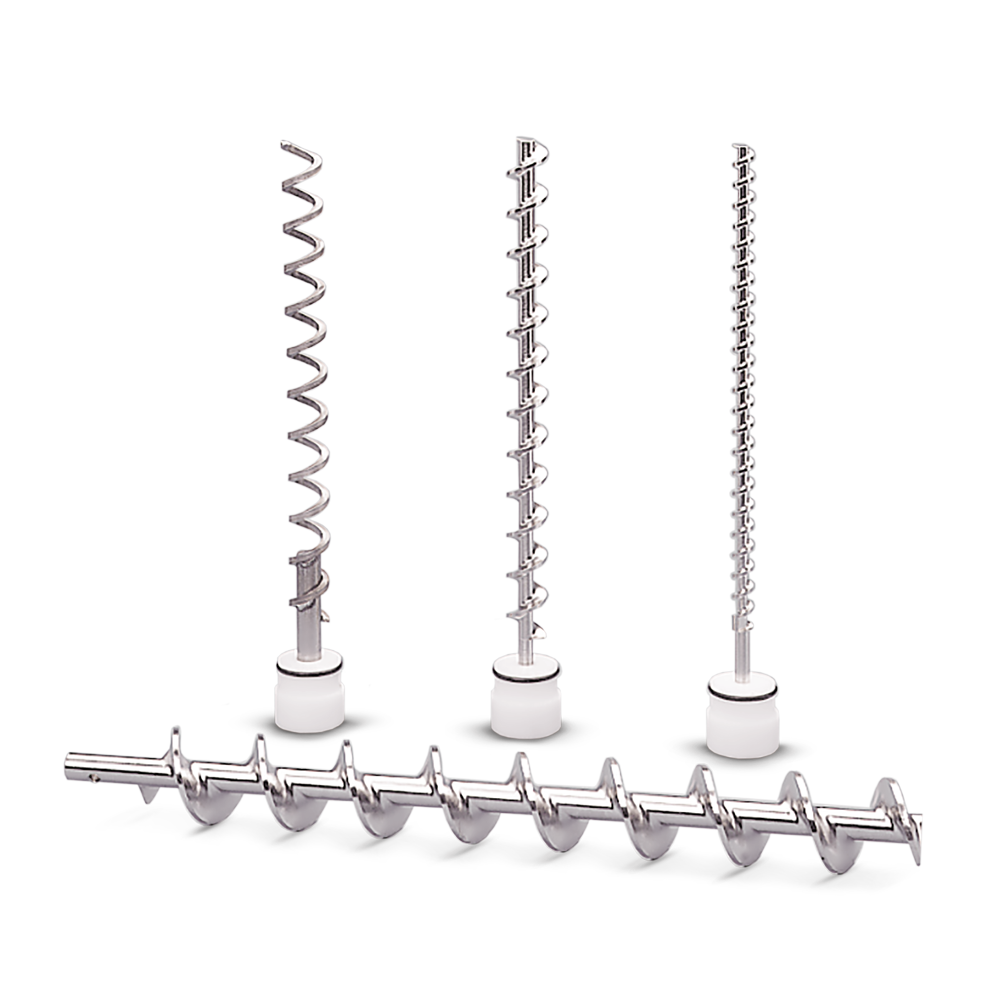

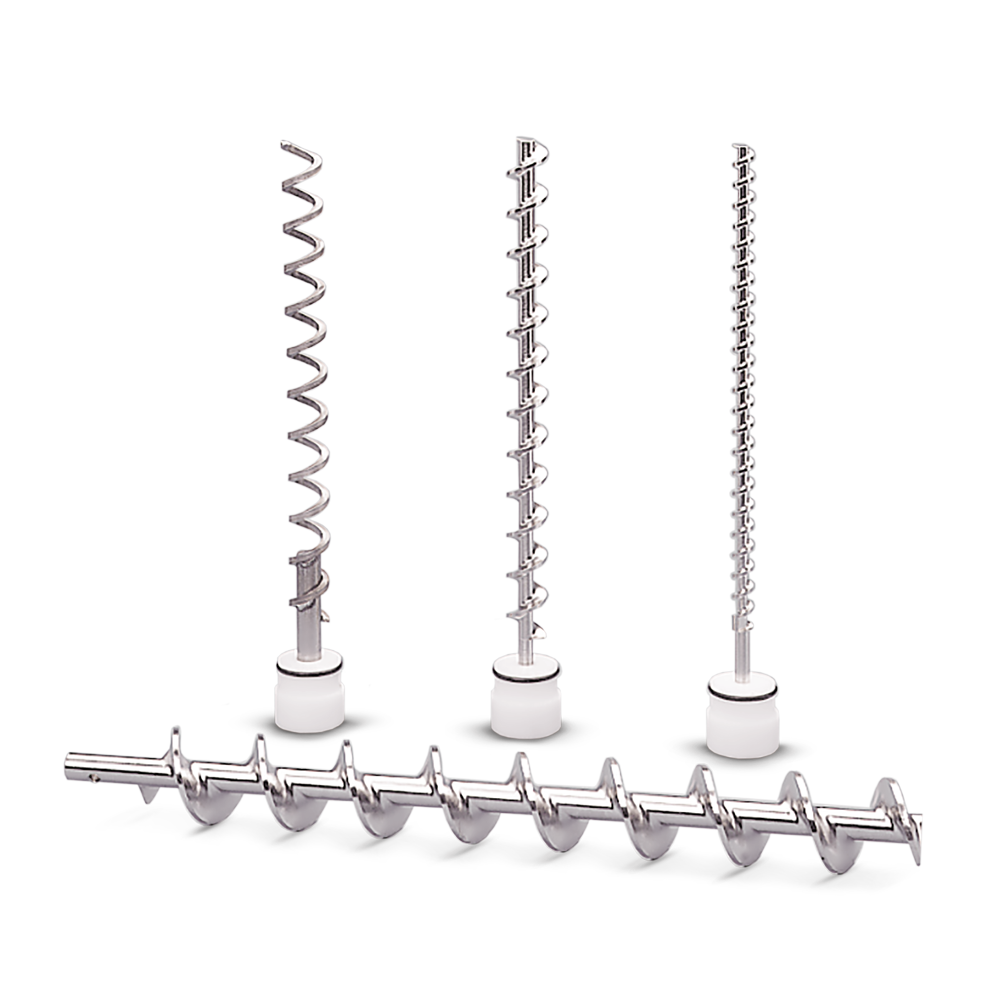

| Powder Feeder Augers | MRF-8, MRF-16 | 1 1/2" and 1" augers for feeding free flowing additive powders. |  |

| Clear-Vu Surge Hoppers | MRF-8, MRF-16 | To easily view material status before material is entering the material line. |  |

| Spare Controllers | MRF-8, MRF-16 | Spare automatic speed controller. Also available with Extrusion Following for extrusion applications. |  |

| Augers with Couplings | MRF-8, MRF-16 | Augers with 1/2", 1" and 2" coupling. |  |

| Auger Tubes | MRF-8, MRF-16 | 1/2", 1", and 2" auger tubes are available. |  |

| Low Level Alarm | MRF-8, MRF-16 | Reduce monitoring requirements by floor personnel with the LLA alarm system, used to signal HGH or LDW material-supply conditions. |  |